Hot Briquetted Iron (HBI) is a high-quality steelmaking feedstock, formed by compressing Direct Reduced Iron (DRI) at high temperatures (typically between 650 and 700°C) into dense briquettes. This process improves handling, reduces reactivity, minimizes the risk of spontaneous combustion, and enhances safety during storage and transportation compared to standard DRI. HBI serves as an efficient and premium alternative to steel scrap, widely used in Electric Arc Furnaces (EAFs) and Induction Furnaces (IFs). Its attributes, such as high density, low porosity, and consistent composition, make it a preferred choice for global steel production.

Hot Briquetted Iron (HBI)

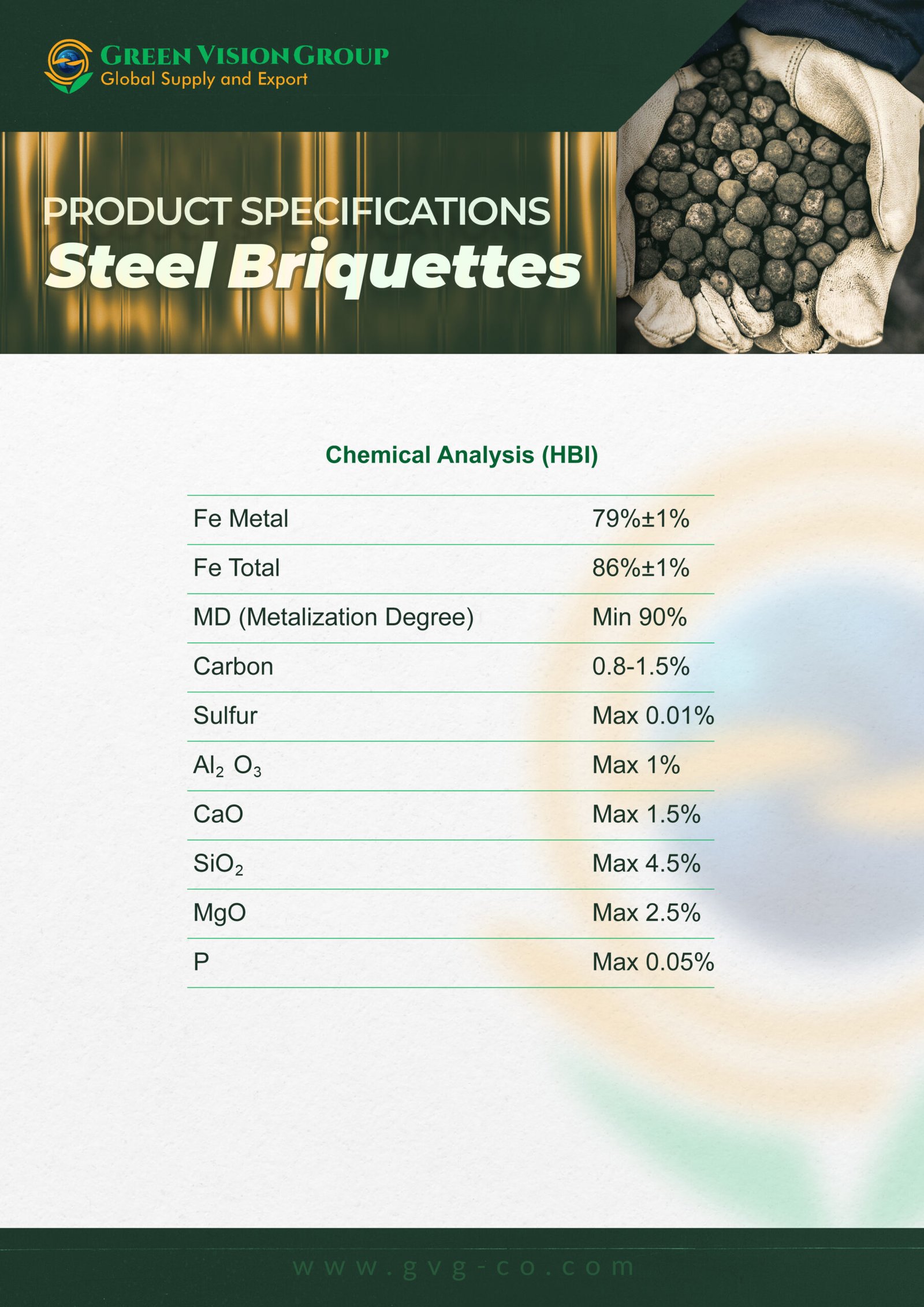

Premium grade Hot Briquetted Iron (HBI) featuring an Fe Metal content of 79% ±1% and Fe Total of 86% ±1%, designed to provide superior purity and reliability for steelmaking processes. With a Metallization Degree exceeding 90%, this HBI ensures exceptional reduction efficiency and dependable performance in both EAF and BOF operations. Its low impurity levels Carbon (0.8–1.5%), Al₂O₃ (up to 1.5%), CaO (up to 1.5%), SiO₂ (up to 4.5%), MgO (up to 2.5%), Phosphorus (up to 0.05%), and Sulfur (up to 0.01%)—enable clean steel production, boost operational efficiency, and minimize slag formation. Perfectly suited for export markets demanding consistent quality and superior metallurgical results.

- الوصف

- Application & Industries

- Technical Specifications

- Standards & Certifications

- Packaging & Export Details

- Quality Contorol

Application & Industries

HBI is widely used in steelmaking processes due to its superior quality and handling characteristics. It is particularly suitable for use in Electric Arc Furnaces (EAFs) and Induction Furnaces (IFs) as a direct charge material, replacing scrap metal. Industries that benefit from HBI include:

- Steel manufacturing and foundries

- Automotive and construction industries

- Shipbuilding and heavy machinery production

- Metal recycling and refining

Technical Specifications

| Parameter | Value |

|---|---|

| Fe Metal | 79% ±1% |

| Fe Total | 86% ±1% |

| Metallization Degree (MD) | Min 90% |

| Carbon | 0.8–1.5% |

| Al₂O₃ | Max 1.5% |

| CaO | Max 1.5% |

| SiO₂ | Max 4.5% |

| MgO | Max 2.5% |

| P | Max 0.05% |

| Sulfur | Max 0.01% |

Standards & Certifications

| ISO 11323 | Defines classification, requirements, and testing methods for sponge iron and HBI products. |

| ASTM E278 / E102 / E877 | Standards for chemical and mechanical testing of iron-based materials. |

| ISRI Specifications | Classifies HBI as a premium scrap metal substitute in steelmaking. |

| Mill Test Certificate (MTC) | Issued with every shipment, providing detailed chemical composition and quality data. |

Packaging & Export Details

- Packaging: Bulk shipments or customized packaging as per client requirements.

- Minimum Order Quantity: As per client request.

- Shipping Destinations: Global markets with high steel production demand.

- Delivery Terms: FOB, CIF, CFR available upon agreement.

Quality Contorol