Iron ore is fundamental to steel production, serving as a critical resource that fuels global infrastructure and manufacturing. Green Vision Group offers premium-grade iron ore distinguished by its high purity, consistent quality, and industrial dependability. Harvested from meticulously selected deposits and refined using advanced beneficiation technologies, this ore satisfies the stringent demands of modern steelmaking. With a base total iron content of 60%, it ensures efficient reduction processes and maximized metal yields across blast furnaces, direct reduction plants, and electric arc furnaces.

The ore primarily comprises hematite and magnetite, appearing as dense, angular fragments with a metallic sheen. Its reddish-brown hue reflects its rich iron oxide composition, while minimal levels of gangue materials reduce processing difficulties. Green Vision Group employs methods such as crushing, screening, magnetic separation, and flotation to boost the ore’s grade while removing impurities like silica and alumina. The result is a product with an optimal granulometry range of 10–40 mm, perfectly suited for furnace charging and seamless material handling.

Application & Industries

Green Vision Group's premium iron ore (Fe≥60%) significantly enhances furnace efficiency and improves metal yield by 10-15%. Its advanced impurity management minimizes costs, reduces coke usage by 8%, and decreases emissions. Consistent sizing optimizes permeability for both blast furnaces and electric arc furnaces, resulting in higher productivity, cleaner steel, and smooth operation throughout sintering and pelletizing processes. Perfectly suited for environmentally sustainable, high-quality steel production.

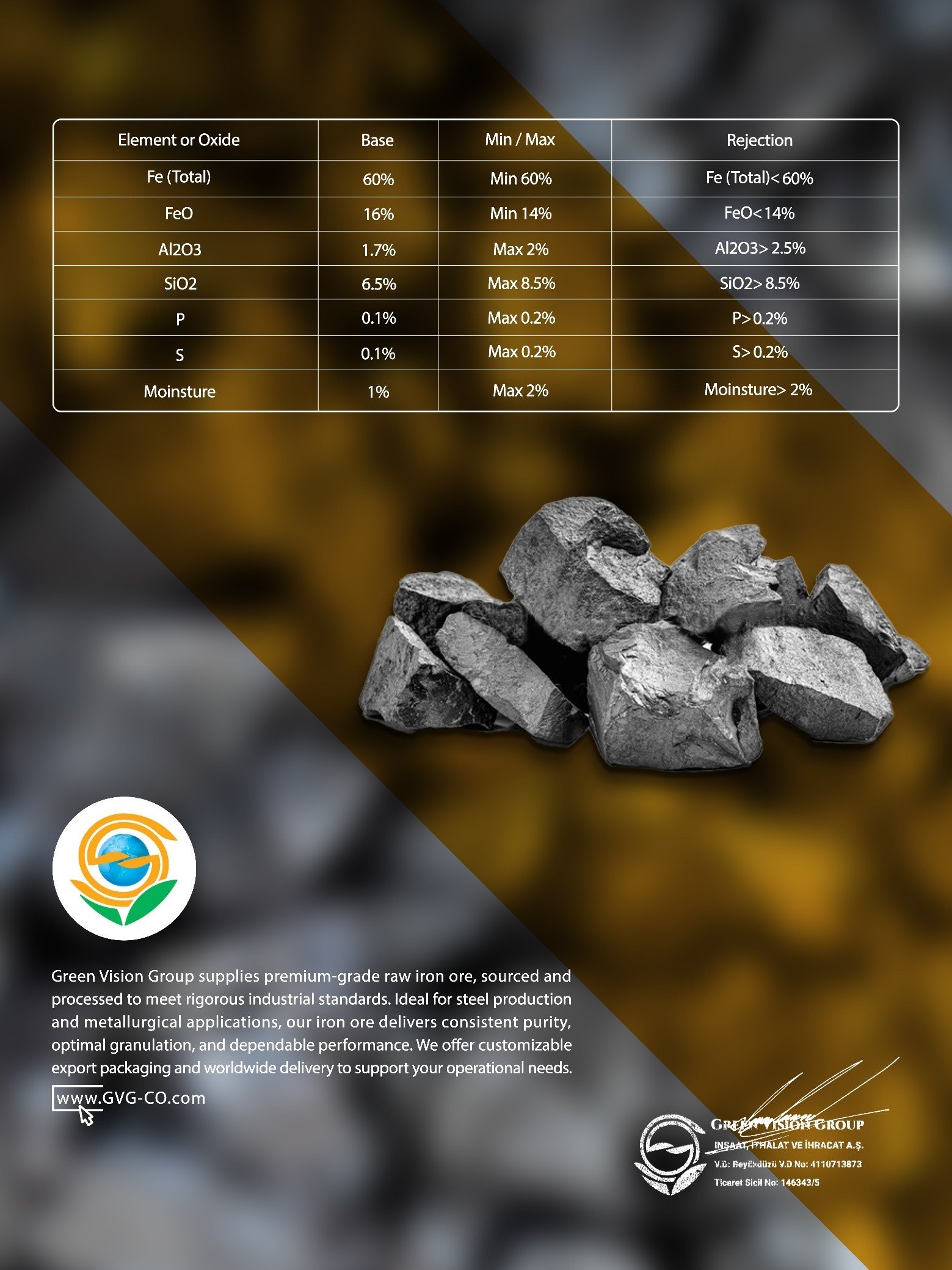

Technical Specification

Chemical Composition

Physical & Metallurgical Properties

Additional Quality Assurance

The product is guaranteed to be free from hazardous contaminants, including heavy metals, radioactive matter, and organic impurities.

Packaging & Export Details

Green Vision Group provides secure and flexible packaging solutions to guarantee the integrity of our iron ore from mine to mill.

Packaging Options

-

Bulk Shipping: Loaded into certified, dry bulk carriers with protective liners to prevent contamination and moisture.

-

Big Bags (FIBC): 1-2 ton, UV-stabilized bags with lifting loops for easy handling and built-in traceability.

-

Small Bags: 25-50 kg palletized bags, ideal for containerized shipping.

Export & Logistics Excellence

-

Efficient Handling: High-speed loading (up to 15,000 MT/day) with dust suppression systems.

-

Quality Assurance: All packaging complies with international standards (ISO 21898, IMDG Code). Pre-shipment hold inspections are standard.

-

Security & Transparency: Shipments are GPS-tracked and accompanied by digital manifests and photo documentation.

Our optimized packaging minimizes handling losses (<0.5%) and supports just-in-time delivery, ensuring a reliable, cost-effective, and sustainable supply chain for our customers.