Steel Slabs are semi-finished steel products with a rectangular cross-section, produced through continuous casting. They serve as a crucial raw material for rolling mills, where they are transformed into flat steel products like hot-rolled and cold-rolled sheets, plates, and coils. Valued for their versatility and strong mechanical properties, steel slabs find applications across industries such as construction, automotive, shipbuilding, and pipeline manufacturing. Typically manufactured in integrated steel plants, slabs are formed by refining molten steel and casting it into large rectangular shapes. This process ensures a consistent chemical composition while minimizing internal defects, making them ideal for producing high-quality steel products.Click here to view Steel Slab

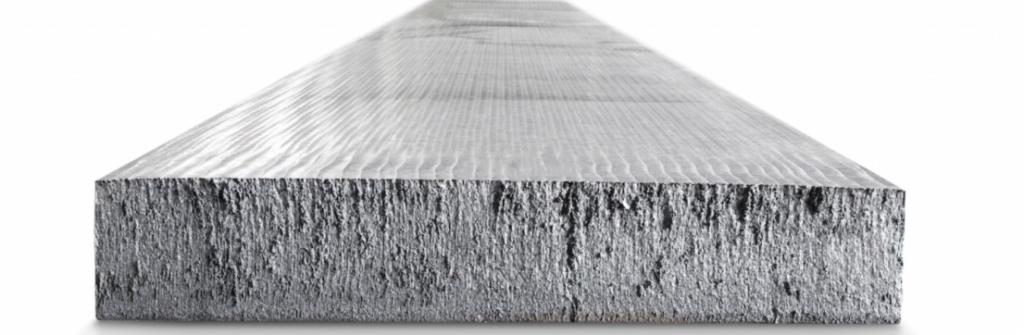

Standard slab thickness ranges from 150 mm to 300 mm, with widths varying between 800 mm and 2200 mm based on customer demands. Individual slabs can weigh several tons, requiring specialized equipment for handling and transport. A significant advantage of steel slabs lies in their adaptability to various manufacturing processes. After casting, slabs undergo hot rolling, where they are heated and reduced in thickness to create steel sheets and plates used in infrastructure, structural applications, and machinery production.

They can also be further processed through cold rolling or galvanization to enhance surface quality and corrosion resistance. However, handling steel slabs presents logistical challenges due to their substantial weight and size. Transport and storage require careful planning, particularly for international shipments. Additionally, fluctuations in raw material prices, such as iron ore and scrap steel, greatly influence slab production costs. Despite these challenges, steel slabs remain a foundational element of the steel industry, playing a critical role in global manufacturing and impacting various industrial and economic sectors. The steel slab is indispensable for modern infrastructure development.

Technical Specifications and International Standards for Steel Slabs

Steel slabs are manufactured under rigorous technical specifications and international standards to ensure high quality and suitability for further processing. A slab’s chemical composition plays a critical role, as it directly influences the mechanical properties of the final steel products. Typically, these slabs are produced from carbon steel, alloy steel, or stainless steel, incorporating varying levels of elements like carbon, manganese, silicon, phosphorus, sulfur, and additional alloys. These materials determine key attributes such as strength, hardness, ductility, and resistance to corrosion.

The mechanical properties of steel slabs include tensile strength, yield strength, elongation, and impact resistance, all dependent on the specific steel grade and production technique used. For instance, low-carbon steel slabs are favored for their high ductility, making them ideal for forming and welding applications. Conversely, high-carbon and alloy steel slabs deliver enhanced strength and wear resistance, catering to heavy-duty industrial needs. To ensure they meet required standards, manufacturers typically conduct comprehensive mechanical testing. Standard dimensions for steel slabs generally range in thickness from 150 mm to 300 mm.

Widths spanning 800 mm to 2200 mm and lengths reaching up to 12 meters define common specifications. However, customized dimensions can also be produced to meet specific customer demands. The surface quality of slabs is crucial, necessitating freedom from defects like cracks, inclusions, and laminations that could compromise the quality of the finished products. Advanced inspection techniques, including ultrasonic and magnetic testing, are commonly utilized to identify both internal and surface-level imperfections. The production and quality of steel slabs are governed by several established international standards.

Standards such as ASTM, EN, DIN, JIS, and ISIRI define permissible chemical compositions and mechanical properties. These frameworks establish dimensional tolerances and testing methodologies for steel slab products. Adhering to these guidelines ensures that steel slabs consistently meet industry requirements. They perform reliably in their intended applications across global markets. Quality assurance remains paramount for steel slab utilization.

Production Process of Steel Slabs

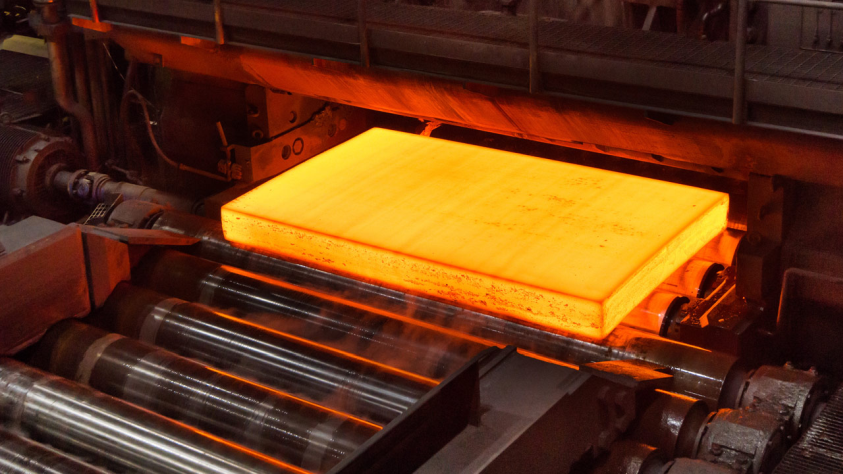

The production of steel slabs involves a series of vital processes, beginning with raw material preparation and culminating in continuous casting. Initially, steelmaking takes place in either Basic Oxygen Furnaces (BOF) or Electric Arc Furnaces (EAF). The BOF method involves combining molten iron from a blast furnace with scrap steel, while the EAF process utilizes scrap steel and direct reduced iron (DRI), melted through high-power electrodes. At this stage, impurities like sulfur, phosphorus, and excess carbon are removed to achieve the required chemical composition. Following the primary steelmaking phase, the molten steel undergoes secondary metallurgy to refine its properties further.

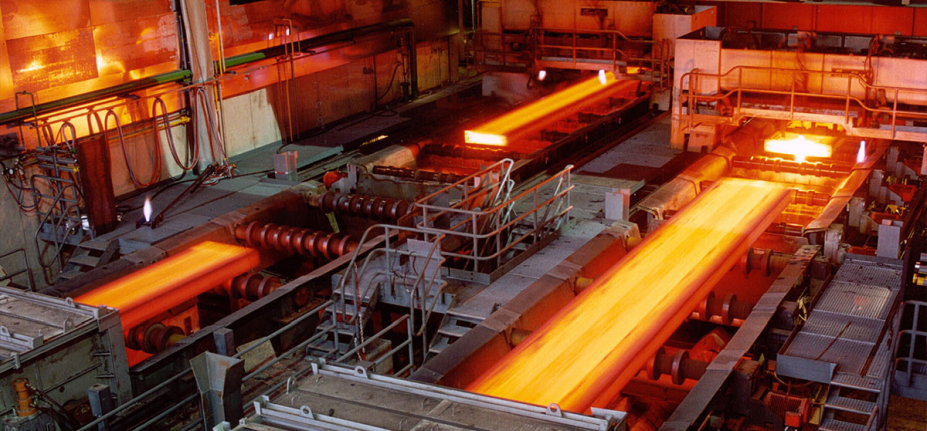

Alloying elements are added during this phase to enhance specific mechanical attributes. Methods such as vacuum degassing, argon stirring, and ladle refining are employed to ensure uniform composition and cleanliness by minimizing non-metallic inclusions. The processed molten steel is then transferred to a continuous casting machine, where it is poured into a water-cooled mold to initiate solidification. During the continuous casting process, the molten steel gradually cools and hardens into rectangular slabs as it progresses through the equipment. Oscillating molds and controlled cooling systems are utilized to ensure uniform solidification and prevent surface defects.

Once the slab is fully formed, high-powered torches or mechanical shears are used to cut it into specified lengths. The slabs are then placed on a cooling bed for further temperature reduction to achieve structural stability. After cooling, slabs are subjected to surface inspection and conditioning to identify and address any defects such as cracks or irregularities. Techniques like grinding or scarfing are used for defect removal. Certain slabs might also go through heat treatment to enhance their mechanical properties before being stored or delivered to rolling mills. This carefully monitored production approach ensures steel slab quality.

Applications of Steel Slabs Across Industries

Steel slabs are a cornerstone of the steel industry, serving as a primary raw material for producing flat-rolled steel products. These products, including hot-rolled and cold-rolled sheets, plates, and coils, are integral to various industrial sectors. Hot-rolled steel, derived from slabs, is widely utilized in construction, shipbuilding, and heavy machinery manufacturing, while cold-rolled steel is favored for automotive applications, home appliances, and precision engineering due to its superior surface finish and enhanced mechanical properties. In construction, steel slabs are processed into structural plates used in bridges, high-rise buildings, pipelines, and pressure vessels.

Their exceptional strength, durability, and ease of fabrication make them well-suited for projects requiring significant load-bearing capabilities. Additionally, slabs are transformed into corrugated roofing sheets and cladding panels, commonly employed in both commercial and residential structures. The automotive sector also heavily depends on steel slabs for manufacturing vehicle body panels, chassis components, and reinforcements. Cold-rolled sheets produced from slabs offer the ideal combination of strength-to-weight ratio, corrosion resistance, and formability essential for modern vehicle design. Many manufacturers further enhance these sheets by galvanizing them with zinc coatings.

This treatment boosts resistance to corrosion, ensuring reliability in outdoor environments. In the oil, gas, and energy industries, steel slabs are crucial for creating large-diameter pipes, pressure vessels, and offshore platforms. These applications demand steel with high toughness, weldability, and resilience to extreme environmental conditions. Similarly, slabs are indispensable in shipbuilding, where they form the hulls, decks, and structural components of ships, guaranteeing strength and longevity in marine settings. The steel slab enables innovation across multiple sectors.

Advantages and Disadvantages of Steel Slabs

Steel slabs present a range of advantages that make them a preferred choice across various industries, though they come with certain limitations that warrant consideration. A key benefit of steel slabs is their versatility in manufacturing a wide array of flat steel products, including hot-rolled and cold-rolled sheets, plates, and coils. This adaptability enables sectors such as construction, automotive, and shipbuilding to efficiently produce both structural and functional components from slabs. Another notable advantage lies in their exceptional mechanical strength and durability. Produced under strict quality control standards, steel slabs exhibit excellent tensile strength, impact resistance, and formability.

These characteristics make them ideal for demanding applications requiring high load-bearing capacity, such as bridges, pipelines, and pressure vessels. Furthermore, the ability to alloy steel slabs with various elements enhances their corrosion resistance, hardness, and weldability, broadening their scope of application. Cost efficiency in large-scale production also adds to their appeal. The continuous casting process used for steel slab production is highly efficient, minimizing material waste while maximizing output. This method allows for bulk production at a lower cost, resulting in more affordable steel products for end users. Additionally, customization options in size and thickness offer flexibility.

However, steel slabs are not without their drawbacks. One significant issue is their considerable weight and large dimensions, which make transportation and handling complex and costly. Specialized equipment like cranes and heavy-duty vehicles is often needed for efficient handling, leading to increased logistical expenses. Another challenge involves their susceptibility to surface defects, such as cracks, inclusions, and oxidation, which can develop during the casting process. Rectifying these issues requires inspections and additional processes like grinding or surface conditioning, thereby raising production costs. Moreover, the steel slab market is subject to fluctuations.

Raw material prices, energy costs, and global demand heavily influence both price stability and availability. In summary, steel slabs offer substantial benefits in terms of versatility, strength, and cost-effectiveness. Challenges related to logistics, surface quality, and market volatility cannot be ignored. By implementing robust quality control measures and optimizing transportation strategies, these limitations can be mitigated. Steel slab reliability supports industrial progress globally.

Factors Influencing the Price of Steel Slabs

The price of steel slabs is shaped by several interconnected factors, as they are a crucial raw material in the steel industry. A key determinant is the cost of raw materials, particularly iron ore, scrap steel, and coal. Since steel slabs are manufactured using either blast furnaces (BOF) or electric arc furnaces (EAF), any fluctuations in these input costs directly influence production expenses and, subsequently, the overall price of slabs. Market demand for steel products is another critical factor. Steel slabs are used to produce hot-rolled and cold-rolled sheets, plates, and coils, making their price sensitive to fluctuations in industries like construction, automotive, shipbuilding, and infrastructure. Click here to view Steel Slab

Periods of economic expansion and heightened construction activity typically drive up demand and prices, whereas downturns in the economy result in reduced demand and lower slab prices. Production costs significantly affect slab pricing as well. These encompass expenses related to energy (electricity, natural gas, and coal), labor wages, and maintenance. Given that steel production is highly energy-intensive, rising costs for fuel or electricity can sharply increase production expenditures. Similarly, labor costs and operational overheads also contribute to the final pricing structure. Exchange rates and international trade policies further influence slab prices, particularly for countries involved in imports or exports.

A stronger local currency may lower the cost of imported slabs, while a weaker currency tends to make them more expensive for domestic buyers. Trade regulations, such as tariffs, import duties, and restrictions imposed by governments, add another layer of complexity to pricing across regions. Lastly, logistics and transportation costs play a prominent role, especially when it comes to global shipments. Since steel slabs are heavy and cumbersome, transportation expenses including shipping fees, port handling charges, and inland freight costs can significantly impact pricing. Supply chain disruptions elevate steel slab costs internationally.

Key Considerations When Purchasing Steel Slabs

When buying steel slabs, several key factors should be carefully evaluated to ensure the product aligns with your specific needs. Start by examining the slab’s chemical composition, focusing on elements such as carbon, manganese, silicon, and other alloys. This ensures the material meets your requirements for strength, durability, and resistance to corrosion. Always request the Mill Test Certificate (MTC) to confirm the steel’s quality and compliance with relevant standards. Next, assess the dimensions of the slab, including its thickness, width, and length. The slab’s size must align with your intended application and subsequent processing requirements.

While custom sizes may be an option, it is crucial to verify the supplier’s ability to fulfill your exact specifications. Pay close attention to the slab’s surface quality. Check for any significant defects like cracks, oxidation, or inclusions that might compromise the final product. Reputable suppliers often conduct thorough quality control checks to ensure the slab’s surface is free from substantial imperfections. Additionally, clarify the pricing and delivery terms before making a purchase. Understand the total cost, potential price variations, and agreed delivery timelines. Logistics are another critical consideration.

Steel slabs are heavy and require specialized arrangements for handling, storage, and transportation. Finally, opt for a dependable supplier with a strong track record and industry reputation for delivering quality products on time. Confirm their certifications and reviews to minimize the risk of problems related to product quality or delayed shipments. The steel slab procurement process demands meticulous attention. Supplier reliability ensures project continuity and material integrity.

Differences Between Billet, Bloom, and Slab

Billets, blooms, and slabs are all classified as semi-finished steel products, yet they vary considerably in size, shape, and their respective roles within the steel manufacturing process. Billets are the smallest of the three, typically produced in a round or square cross-section with dimensions ranging from 40 mm to 150 mm. These are most commonly used as the base material for manufacturing long products like bars, rods, and wire. Further processing involves heating billets in rolling mills to shape them into the desired final forms. Due to their smaller size and manageable dimensions, billets are especially suited for applications requiring precise shaping and detailed craftsmanship. Click here to view Steel Slab

Blooms fall between billets and slabs in terms of size, featuring a larger cross-sectional area, typically between 150 mm and 400 mm. They are often used to produce beam blanks, structural components, rails, and medium-sized steel plates. Like billets, blooms are also processed in rolling mills but cater to applications demanding thicker and stronger materials. Products made from blooms often include I-beams or H-beams, which are vital for heavy structural applications. Slabs, being the largest of the three, have a distinctly rectangular shape with typical dimensions ranging from 150 mm to 300 mm in thickness, 800 mm to 2200 mm in width, and lengths up to 12 meters.Click here to view Steel Bloom

Their primary role lies in serving as raw material for flat-rolled products such as sheets, coils, and plates. Slabs are processed in plate mills or hot-rolling mills to create these flat materials, which find extensive use in various industries like construction, automotive manufacturing, and shipbuilding. Though billets, blooms, and slabs share a common purpose as intermediate steel products, their distinctive characteristics make them suitable for different applications. Billets are tailored for producing smaller long products such as rods and wire, blooms serve medium-sized structural needs like beams, and slabs are essential for creating flat products. Understanding these differences is pivotal for steel manufacturers.

Global Standards and Future Outlook for Steel Slabs

International standards shape the global steel slab market by setting quality benchmarks. They establish trust among manufacturers, exporters, and consumers reliably. Products become consistent, comparable, and assessable through these frameworks. This enhances transparency and simplifies international trade processes. Without standards, risks of low-quality products increase significantly. Testing costs and material adaptation expenses would rise unnecessarily. Adhering to standards facilitates steel slab export and import efficiently. Countries aligned with global standards gain easier market access. Competitiveness improves while market diversity broadens considerably. Standards enable manufacturers to tailor products for specific markets.

Innovation drives market share expansion through quality improvements. Safety and longevity of global structures depend on these benchmarks. Climate variations and load conditions require universal material standards. They reduce structural failures from defects or insufficient load management. Infrastructure integrity remains protected while business reputations stay intact. Standards minimize commercial risks in cross-border transactions effectively. Clear criteria reduce disputes and legal complications substantially. Contract execution and project delivery become streamlined processes. Investor confidence grows with standardized quality expectations. International companies participate more actively in global markets. Technological advancement accelerates across the entire industry.

Manufacturers adopt stricter requirements and upgrade processes continuously. Waste reduction and better environmental practices emerge naturally. High-quality adaptable materials benefit the entire construction sector. Sustainable growth and healthy competition characterize compliant markets. Rigorous safety and performance expectations become industry norms universally. Evolving technologies and environmental demands necessitate constant updates to steel slab standards. Robust collaboration among institutions and authorities is crucial for progress. Transparency minimizes commercial risks while fostering investor confidence. Digital transformation enhances traceability through modern solutions. Rapid technological advancement demands quicker norm revisions urgently. Staying competitive requires expediting approval processes internationally. The steel slab remains central to global development. Click here to view Steel Slab

Understanding steel slabs as semi-finished products from continuous casting is a helpful clarification. I found a related overview of material properties on https://seed3d.ai that might be useful for further research.