Cutback Bitumen is a liquid form of bitumen blended with volatile solvents such as kerosene or naphtha to temporarily lower its viscosity. This allows for easier application at ambient temperatures, eliminating the need for extensive heating equipment. Once applied, the solvent evaporates, leaving behind a durable and adhesive bituminous binder. Depending on the evaporation rate of the solvent, Cutback Bitumen is categorized into Rapid Curing (RC), Medium Curing (MC), and Slow Curing (SC) grades.

Cutback bitumen

Cutback bitumen is a liquid bitumen blend made by dissolving pure bitumen in petroleum solvents (gasoline, kerosene, or diesel). It flows easily at ambient temperatures, eliminating the need for excessive heating. Used in road priming, tack coats, and cold mix asphalt, it offers quick curing (RC, MC, SC grades) and deep penetration. Though cost-effective, its solvent emissions raise environmental concerns compared to emulsified bitumen. Green Vision Group supplies high-quality cutback bitumen compliant with ASTM, ISO, and EN standards for global infrastructure projects.

- الوصف

- Quality Contorol

- Key Benefits

- Technical Specification

- Application & Industries

- Packaging & Export

- Standards & Certifications

Quality Contorol

Key Benefits

- Cold Application – Requires no heating, reducing energy consumption and enhancing on-site safety.

- Improved Penetration – Ensures excellent adhesion and penetration, particularly on dry or aged aggregates.

- Flexible Curing Rates – Available in various grades suited for different climates and construction needs.

- Easy Handling & Storage – Remains fluid at room temperature, simplifying transportation and application.

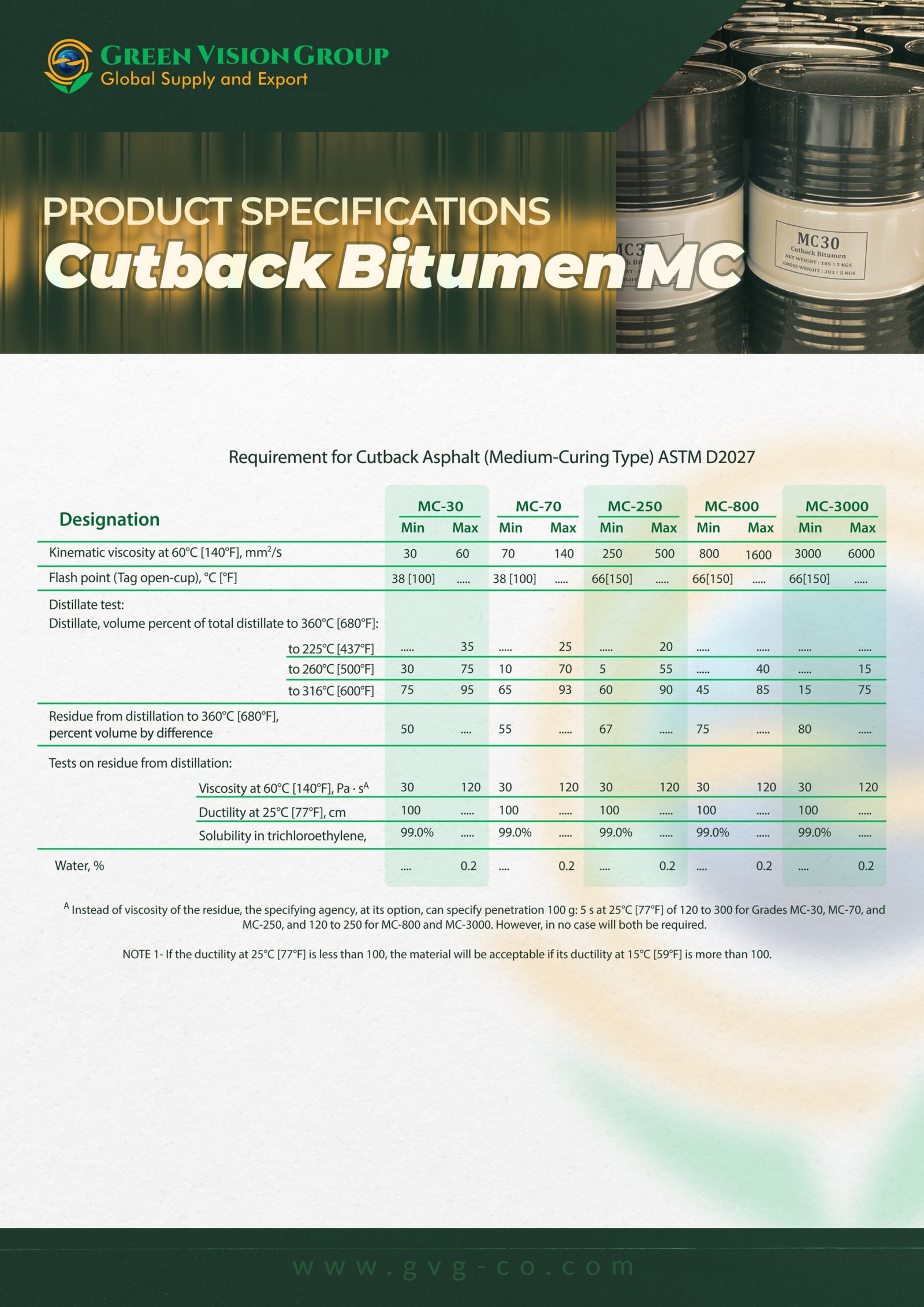

Technical Specification

| Kinematic Viscosity (60°C) | 100–500 cSt (ASTM D2170) |

| Flash Point (Tag Closed Cup) | Min. 38°C (ASTM D3143) |

| Distillation Loss (225°C) | Max. 10% (ASTM D402) |

| Residue by Evaporation | Min. 55% (ASTM D402) |

| Penetration of Residue | 100–250 dmm (ASTM D5) |

| Ductility of Residue (25°C) | Min. 100 cm (ASTM D113) |

| Solubility in Trichloroethylene | Min. 99% (ASTM D2042) |

Application & Industries

- Road Surface Treatments & Prime Coating – Used in prime coats, tack coats, and surface dressing for roads requiring quick curing.

- Cold-Mix Asphalt & Temporary Patching – Ideal for cold-mix asphalt production and road repair applications in remote or cold regions.

- Dust Suppression & Soil Stabilization – Applied for dust control and strengthening loose soil structures in infrastructure projects.

Packaging & Export

- Packaging Options:

- New Steel Drums (150 kg net capacity)

- Bulk supply via tankers or flexi-tanks

- IBC Containers (available upon request)

- Export & Logistics Information:

- HS Code: 27132000

- Country of Origin: Iran

- Shipping Options: FOB (Tailored to customer preferences)

- Packaging: Standard palletized and shrink-wrapped for drum shipments

- Custom Labeling: Available upon request

Standards & Certifications

- ASTM D2027 / D2028 – Specifications for Rapid & Medium Curing cutback asphalt.

- AASHTO M81 / M82 – US road authority standard for cutback bitumen grades.

- ISO 9001:2015 – Quality Management System Certification.

- REACH Compliant (EU) – Ensures compliance with European Union chemical safety regulations.

- SGS / BV Inspection (Optional) – Independent third-party pre-shipment quality and quantity verification.