Alloy steel rebar is a premium–grade reinforcement material engineered to withstand the stringent demands of modern, complex construction projects. By incorporating controlled quantities of alloying elements like chromium, manganese, nickel, and molybdenum into carbon steel, its mechanical and chemical properties are significantly enhanced. These enhancements result in increased yield strength, tensile strength, toughness, and overall structural efficiency, making alloy steel rebar an excellent choice for applications requiring superior load-bearing capacity and long-term durability. One of its primary benefits lies in its heightened resistance to corrosion, abrasion, and environmental wear and tear. This is particularly advantageous in harsh conditions like high–humidity regions, coastal and marine environments, chemically aggressive zones, and areas prone to extreme temperature fluctuations. Such resistance helps extend the lifespan of reinforced concrete structures, substantially minimizing maintenance and repair costs over time. Additionally, alloy steel rebar boasts exceptional fatigue resistance, making it highly effective in withstanding repetitive or dynamic loads. This type of rebar is widely employed in critical infrastructure initiatives such as high-rise buildings, long-span bridges, tunnels, marine installations, offshore structures, power plants, industrial facilities, refineries, and large-scale foundations. Its advanced mechanical properties allow engineers to optimize structural designs, often enabling a reduction in the volume of reinforcement required without compromising strength or safety. Depending on its alloy composition and manufacturing process, the rebar can also feature excellent weldability and formability, facilitating efficient fabrication and seamless on-site installation. Produced in compliance with internationally recognized standards, alloy steel rebar undergoes stringent quality control measures including chemical composition analysis, tensile and yield strength evaluations, and dimensional inspections. Available in diverse diameters, lengths, and grades, it can be customized to meet specific technical specifications for various projects. This combination of high strength, durability, and resilience under challenging conditions makes alloy steel rebar a dependable solution for demanding construction environments where performance and reliability are paramount.

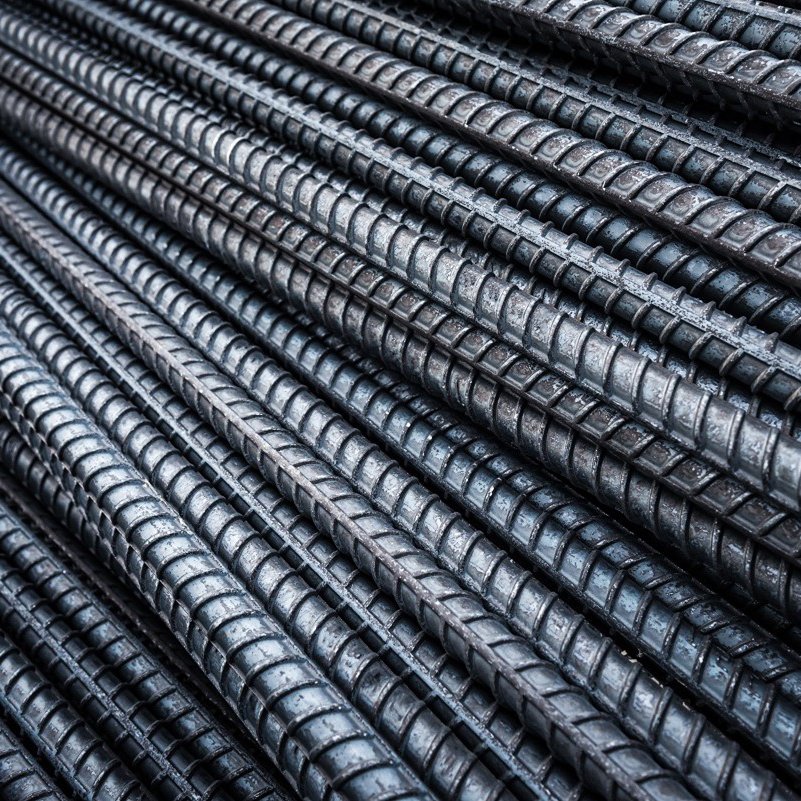

Alloy Rebar

Alloy steel rebar is a premium reinforcement bar enhanced with chromium, manganese, nickel, and molybdenum for exceptional strength (450-1000 MPa) and corrosion resistance. Designed for demanding environments, it outperforms standard rebar in marine, industrial, and seismic applications.

Meta Description:Alloy steel rebar (450-1000MPa) for extreme environments. Corrosion-resistant, seismic-proof reinforcement for marine, industrial & high-rise projects. ASTM/BS certified.

فئاتRebar

Technical Specifications

| Product Type | Alloy Steel Rebar |

| Material | Alloy steel with Chromium, Manganese, Nickel, Molybdenum |

| Diameter | 10 mm to 50 mm |

| Length | 6 meters to 12 meters |

| Yield Strength | 450 MPa to 800 MPa |

| Tensile Strength | 600 MPa to 1000 MPa |

| Packaging | Bundled with steel straps |

| Weldability | Weldable (with consideration for alloy composition) |

Application & Industries

Alloy steel rebars are widely used in:

- High-rise buildings and infrastructure projects

- Bridges and highway constructions

- Marine and coastal structures

- Industrial and petrochemical plants

- Earthquake-resistant constructions

- Corrosive environments requiring enhanced durability

Standards & Certifications

Alloy steel rebars comply with international standards, including:

- ASTM A706 – Specification for alloy reinforcement steel

- BS 4449 – British standard for reinforced steel bars

- DIN 488 – German standard for reinforcing steel

- ISIRI 3132 – Iranian standard for alloy steel rebars

- GOST 5781 – Russian standard for steel reinforcement

منتجات ذات صلة

"" تم الإضافة إلى السلة الخاصة بك.عرض السلة