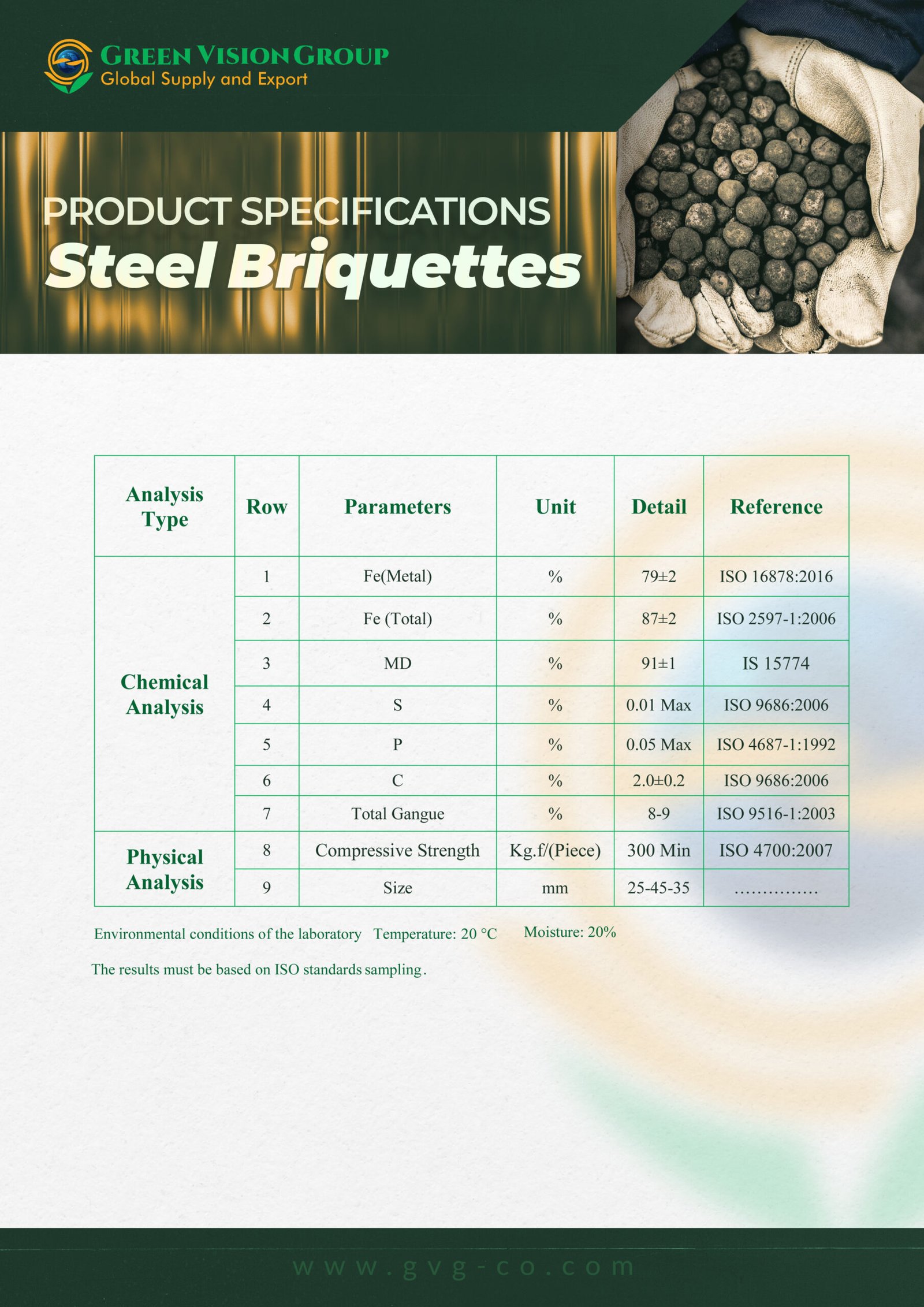

Cold Briquetted Iron (CBI) is a dense metallic material created by compressing Direct Reduced Iron (DRI) at room temperature. This process addresses the challenges of reoxidation, dust generation, and operational difficulties often associated with sponge iron. Thanks to its compact structure and high iron content, CBI serves as an excellent alternative to scrap metal and sponge iron in electric arc furnaces (EAF) and induction furnaces in the steelmaking sector. It offers consistent chemical composition, improved energy efficiency during melting, and hassle-free storage and transportation, particularly for bulk exports. Widely utilized in the production of billets, slabs, and other steel products, CBI has become a preferred raw material for steel manufacturers globally.

Why Choose CBI Over DRI?

- Enhanced Safety & Stability: Unlike DRI, CBI is highly resistant to oxidation and spontaneous combustion, making it safer for transportation and storage.

- Higher Bulk Density: CBI has a density of approximately 5.0 g/cm³, which improves furnace efficiency and reduces handling losses.

- Lower Dust & Fines Generation: Due to its compact form, CBI minimizes material loss and environmental contamination during processing.

- Cost-Effective in Shipping & Storage: With improved packing efficiency and better mechanical strength, CBI is an economical option for bulk exports.

- Consistent Chemical Composition: Ensures predictable melting behavior and optimal steel quality.