Bitumen 40/50 is a premium grade penetration bitumen commonly utilized in demanding construction projects such as highways, expressways, airport runways, and industrial pavements. Manufactured through the controlled air blowing process of vacuum residue, this grade features a penetration range of 40/50, which makes it harder and more durable than grades like 60/70 or 80/100. This makes it particularly suitable for hot climates and regions experiencing heavy traffic loads. Known for its strong adhesive properties, high viscosity, and a softening point typically above 49°C, Bitumen 40/50 ensures robust asphalt performance, providing long-lasting pavement stability. It is highly resistant to deformation, varying temperatures, and intense mechanical stress, making it a reliable choice under demanding conditions. In addition to road infrastructure, it finds applications in waterproofing, insulation, roofing, and corrosion protection due to its excellent impermeability and resistance to oxidation. Produced in alignment with ASTM D946 standards, Bitumen 40/50 guarantees consistent quality and dependability, earning its reputation as a preferred option for extensive projects in regions like the Middle East, Africa, and South Asia.

Bitumen 40/50

Bitumen 40/50 is a hard, penetration grade material extensively utilized for high performance road construction and heavy-duty pavements. Boasting a penetration range of 40–50 and a softening point of approximately 49°C, it delivers exceptional heat resistance, strong adhesion properties, and remarkable durability under intense traffic conditions. This grade is particularly suitable for highways, airport runways, industrial paving, and areas with hot climates. Produced in compliance with ASTM D946 standards, Bitumen 40/50 serves as a dependable and durable binder, widely applied in infrastructure projects, waterproofing solutions, and protective coatings around the world.

- الوصف

- Key Benefits

- Technical Specifications

- Packaging & Export

- Standards and Certifications

- Quality Contorol

Key Benefits

-

Excellent Heat Resistance

With a high softening point (≈49°C+), Bitumen 40/50 maintains stability under extreme temperatures, reducing rutting and bleeding in hot and tropical climates. -

Superior Load-Bearing Strength

Its hardness and rigidity minimize deformation and fatigue cracking, making it ideal for highways, airport runways, and industrial pavements exposed to heavy traffic. -

Strong Adhesion to Aggregates

Exceptional bonding properties ensure compact, durable asphalt mixes, effectively preventing issues such as raveling, potholes, and stripping. -

Outstanding Water and Oxidation Resistance

Its hydrophobic and anti-oxidation characteristics protect pavements in humid or rainy environments, enhancing long-term durability. -

Reliable Long-Term Performance

Balanced penetration and viscosity help the material resist aging while maintaining flexibility and stability, leading to smoother roads and reduced maintenance costs. -

Versatile Industrial Applications

Beyond paving, Bitumen 40/50 is widely used in waterproofing, roofing, pipe coatings, and protective sealants due to its excellent moisture resistance.

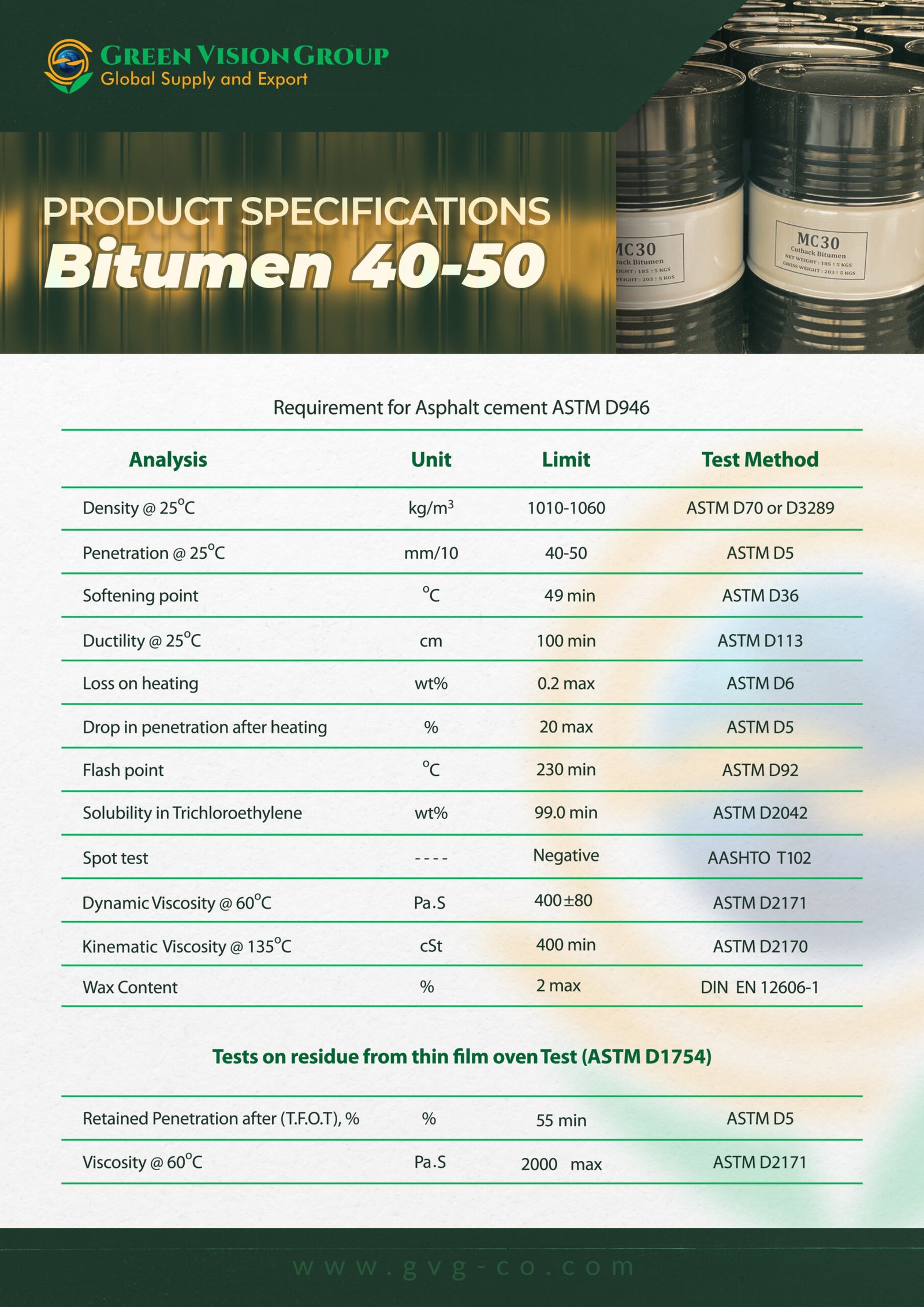

Technical Specifications

Technical Specifications – Bitumen 40/50

| Property | Specification | Test Method |

|---|---|---|

| Penetration at 25°C | 40–50 (0.1 mm) | ASTM D5 |

| Softening Point | ≥ 49°C | ASTM D36 |

| Density at 25°C | 1010–1060 kg/m³ | ASTM D70 |

| Ductility at 25°C | ≥ 100 cm | ASTM D113 |

| Flash Point | ≥ 230°C | ASTM D92 |

| Loss on Heating | ≤ 0.2% | ASTM D6 |

| Penetration After Heating | ≥ 55% (max 20% reduction) | ASTM D5 (After TFOT) |

| Solubility | ≥ 99% | ASTM D2042 |

| Dynamic Viscosity at 60°C | 400 ± 80 Pa·s | ASTM D4402 |

| Kinematic Viscosity at 135°C | ≥ 400 cSt | ASTM D2170 |

| Wax Content | ≤ 2% | ASTM D721 |

| TFOT Residue – Viscosity at 60°C | ≤ 2000 Pa·s | ASTM D1754 |

| TFOT Residue – Retained Penetration | ≥ 55% | ASTM D1754 |

Packaging & Export

Bitumen 40/50 is carefully packaged and transported in line with individual customer needs and international transport regulations, ensuring safe handling and efficient global delivery.

New Steel Drums

As the most widely used export method, new steel drums (net weight 180–200 kg) provide high durability and leak resistance, suitable for both land and sea transportation. A standard 20-foot container accommodates approximately 110–120 drums, making it highly efficient for general global shipments.

Bitutainers and Flexi Bags

For bulk or large-scale requirements, bitutainers ISO certified containers with inbuilt heating coils offer a secure and economical packaging solution. Flexi bags are another practical option for bulk transport, particularly when heating facilities are available at the destination.

Bulk Shipments

For large volumes, bulk transport using insulated tankers or vessels is the most cost-effective solution. This method ensures temperature stability and minimizes packaging waste, ideal for high-volume consumption.

Storage and Handling Guidelines

Store in dry, covered tanks away from direct sunlight - Recommended storage temperature: 150–165°C - Maximum pumping/mixing temperature: not exceeding 180°C - Ensure proper ventilation, fire safety protocols, and the use of protective gear - Clearly label all containers with grade, batch number, weight, and country of origin to comply with export standards This comprehensive packaging and export framework guarantees that Bitumen 40/50 reaches customers worldwide in safe, efficient, and optimal condition.

Standards and Certifications

Bitumen 40/50 is produced and tested in line with stringent international standards to maintain consistent quality, reliability, and performance. It adheres completely to:

ASTM D946 – Standard Specification for Penetration-Grade Asphalt Cement

AASHTO M20 – Standard Specification for Road and Paving Bitumen

EN 12591 – European Standard for Paving Grade Bitumen

Every batch is rigorously tested for penetration, softening point, ductility, and solubility before being dispatched. Leading manufacturers employ certified management systems such as:

ISO 9001 – Quality Management

ISO 14001 – Environmental Management

ISO 45001 – Occupational Health & Safety

Independent inspection agencies like SGS, Bureau Veritas, and Intertek provide test reports and certificates of conformity, ensuring transparency and reliability.

By meeting these demanding global standards, Bitumen 40/50 ensures safety, longevity, and environmental compatibility for road construction and industrial uses. Its compliance also supports smooth international trade across regions including the GCC, South Asia, Africa, and Europe

Quality Contorol