Bitumen grade 120/150 is a medium-soft penetration grade bitumen, commonly employed in road surfacing, maintenance overlays, and general waterproofing applications within construction projects. Compared to harder grades like 40/50 or 60/70, the 120/150 grade reflects a penetration range of 120 to 150 deci-millimeters at 25°C, assessed under standard testing conditions. A higher penetration value indicates a softer binder, which provides greater flexibility, enhanced adhesion in colder temperatures, and easier mixing and handling. When used as a binder in hot mix asphalt (HMA), Bitumen 120/150 proves particularly beneficial for projects requiring superior workability. This grade excels in moderate-to-cold climates or in rehabilitation tasks where fatigue resistance, crack prevention, and long-term durability are critical. Its softer composition enables asphalt mixes to be produced at lower temperatures or with higher proportions of reclaimed asphalt pavement (RAP), fostering more sustainable construction approaches. In an international context, the term “Bitumen 120/150 for export” highlights the significance of this grade in global markets. Countries across regions like Asia, Africa, and the Gulf frequently specify Bitumen 120/150 for pavement designs that require enhanced flexibility—an essential feature in environments with high traffic loads and limited paving temperature windows. Suppliers marketing themselves as “pengrade bitumen 120/150 suppliers” gain a competitive advantage by fulfilling these criteria. This particular grade is typically derived from vacuum-distilled residual oils, which are further processed—through methods such as blowing or modification—to meet the stipulated penetration range. The 120/150 grade achieves a critical balance between workability and resilience; while excessively soft binders may deform in hot climates, Bitumen 120/150 offers stability coupled with toughness ideal for cooler regions. For exporters targeting inquiries like “Buy Bitumen 120/150” online, emphasizing its versatility for rehabilitation overlays, flexible pavements, and functionality across diverse climates can significantly enhance market visibility and attract buyers. Key selling points such as innovative packaging options, rigorous quality assurance, compliance with international standards, and seamless export documentation can further strengthen their competitive position. In conclusion, Bitumen 120/150 remains a versatile and highly sought-after penetration grade binder. It serves as an economical, practical, and climate-adaptive solution tailored to the needs of paving contractors, government infrastructure projects, and importers engaged in road construction and waterproofing initiatives.

Bitumen 120/150

Bitumen 120/150 is a medium-soft penetration–grade material widely applied in road construction, maintenance projects, and waterproofing solutions. With a penetration range of 120–150 dmm at 25°C, it delivers excellent flexibility, reliable adhesion in colder climates, and ease of handling during mixing operations. Its softer nature makes it especially suitable for moderate to cold regions, providing enhanced fatigue resistance, effective crack prevention, and greater durability in hot mix asphalt (HMA). Furthermore, Bitumen 120/150 enables lower mixing temperatures, supporting the increased use of reclaimed asphalt pavement (RAP), which aligns with more sustainable construction practices. This grade is internationally recognized as a dependable, versatile, and highly preferred choice for a wide range of infrastructure projects.

Key Benefits

1. Enhanced Workability and Mix Production

The penetration range of 120–150 dmm allows asphalt plants to operate at lower temperatures, while also supporting higher incorporation of reclaimed asphalt pavement (RAP) without compromising stiffness or causing brittleness. This characteristic makes it particularly suitable for rehabilitation and overlay projects where managing thermal cracking is crucial.

2. Superior Flexibility and Crack Resistance

Bitumen 120/150 excels in resisting fatigue cracking and thermal shrinkage, especially in regions experiencing temperature variations. Its high flexibility aids in absorbing pavement movements, extending the service life of roads when compared to harder grades.

3. Reliable Performance in Moderate to Cold Climates

This grade ensures stability and a smooth surface across diverse temperature conditions. It remains flexible in colder climates and resists deformation during warmer weather, providing dependable performance year-round.

4. Sustainability and Recycling Benefits

The ability to effectively utilize higher quantities of reclaimed asphalt pavement (RAP) makes Bitumen 120/150 a key component in eco-friendly construction practices. By minimizing the need for virgin materials, it aligns with sustainability standards in modern road building.

5. Economical and Cost-Effective Solution

Offering a balanced blend of performance and affordability, Bitumen 120/150 is a budget-friendly alternative to harder penetration grades or polymer-modified binders. This makes it an attractive option for contractors, government projects, and exporters seeking cost-effective materials.

6. Wide Acceptance and Global Compliance

Commonly specified in standards for overlays, maintenance works, and secondary roads, this grade is widely recognized in international markets. Its versatile performance meets the demands of diverse projects, enhancing visibility for search terms such as Penetration Grade Bitumen 120/150 Supplier or Buy Bitumen 120/150.

Standards and Certifications

In the highly competitive road-paving materials industry, adhering to international standards and obtaining independent certifications is crucial for exporters of Bitumen 120/150. Buyers looking for terms like Buy Bitumen 120/150 Export or Penetration Grade Bitumen 120/150 Supplier expect dependable products supported by verified technical credentials.

Bitumen 120/150 must conform to universally accepted technical standards, including:

- ASTM D946 / AASHTO M20: U.S. standards outlining essential test methods for penetration-grade bitumen.

- EN 12591: European standard for paving-grade bitumen.

- ISO 9001:2015: Certification for quality management, ensuring consistent production processes.

- ISO 14001:2015: Certification for environmental management, signifying sustainable operational practices.

To enhance buyer confidence, reliable suppliers often incorporate third-party inspections and testing by reputable organizations such as SGS, Bureau Veritas, or Intertek. Export packages typically include critical documents like the Certificate of Quality and Quantity (COQ), Certificate of Analysis (CoA), and compliance records such as REACH certifications or relevant local environmental approvals.

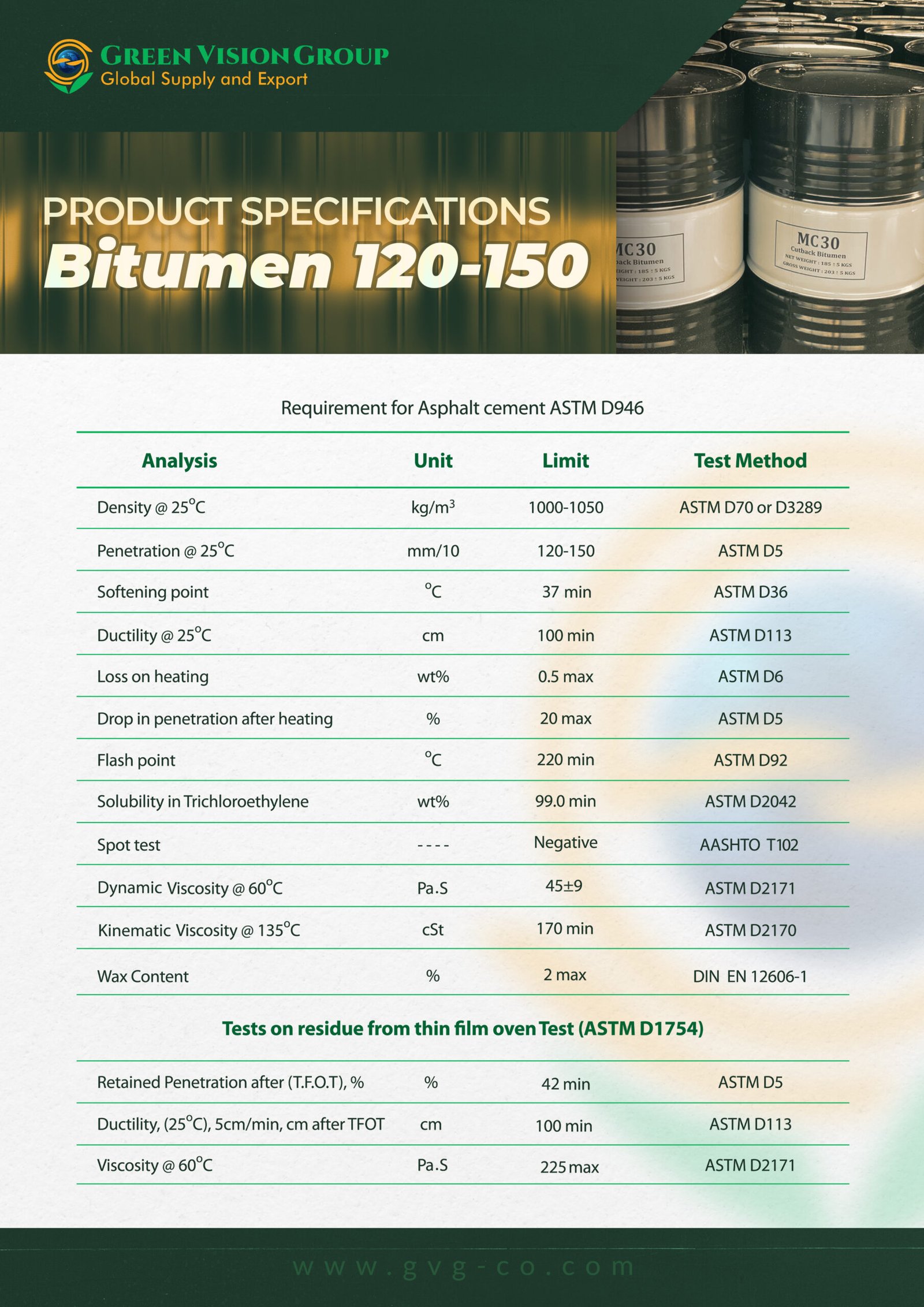

Technical Specification

Bitumen 120/150 – Standard Technical Properties

| Property | Test Method | Standard Range |

|---|---|---|

| Penetration @ 25°C (0.1 mm) | ASTM D5 | 120 – 150 |

| Softening Point (°C) | ASTM D36 (R&B) | 38 – 46 |

| Ductility @ 25°C (cm) | ASTM D113 | ≥ 80 |

| Flash Point (°C) | ASTM D92 | ≥ 230 |

| Specific Gravity @ 25°C | ASTM D70 | 1.01 – 1.05 |

| Solubility in TCE (%) | ASTM D2042 | ≥ 99.0 |

| Loss on Heating (5 hr @ 163°C) | ASTM D6 | ≤ 0.5% |

| Penetration after Heating (%) | ASTM D5/D6 | ≤ 20% drop |

| Viscosity @ 135°C (cSt)(optional) | ASTM D2170 | 270 – 450 |

| Aging Resistance (TFOT)(optional) | ASTM D1754 | Compliant |

Packaging

Effective packaging and logistics are essential in maintaining product integrity and ensuring the safe, efficient delivery of goods across international borders. Bitumen 120/150 is offered in various export-ready formats tailored to project requirements, import regulations, and storage solutions.

Steel Drums

Steel drums are the most commonly used packaging option for international shipments.

- Net Weight: 180 ± 3 kg per drum

- Container Capacity: Approximately 20 tons per 20-ft container

These drums are heat-resistant, fully leak-proof, and equipped with a bitumen-friendly lining. This packaging format is ideal for buyers who prioritize standardized and reliable shipping solutions.

Bitubags (Jumbo Bags)

Bitubags, capable of holding 1 metric ton of bitumen, provide several advantages:

- Reduced packaging waste

- Simplified handling and storage

- Convenient direct melting at asphalt plants

Thanks to these benefits, importers frequently search for options like “Bitumen 120/150 for Export Bulk Bag.

Bulk Tanker Delivery

For large-scale or extended projects, bulk delivery is a highly cost-effective solution:

- Transportation of molten bitumen via road tankers or tanker vessels

- Eliminates the need for additional packaging

- Reduces waste while offering a lower cost per unit

This method is particularly suitable for major construction projects and contracts requiring continuous supply.

Quality Contorol