Polybutadiene Rubber1220(PBR) is a premium-grade Polybutadiene Rubber1220(PBR) engineered to meet the demands of applications requiring high elasticity, durability, and exceptional resistance to dynamic fatigue. As a high cis Polybutadiene Rubber1220(PBR) manufactured using advanced catalyst technology, predominantly Neodymium based, it features outstanding structural consistency, low hysteresis, and superior mechanical strength even under prolonged stress. This specialized rubber is designed for industries where precision, durability, and energy efficiency are crucial, including high-performance tire production, industrial rubber components, and high-impact molded parts. One of the key attributes of Polybutadiene Rubber1220(PBR) is its high cis-1,4 content, typically exceeding 96%. This molecular composition enhances its elasticity, wear resistance, and molecular alignment, ensuring flexibility at extremely low temperatures alongside excellent tensile strength. These characteristics make it an ideal choice for products that need to perform reliably in cold conditions or under extended mechanical stress. Additionally, the uniform molecular structure minimizes heat generation during dynamic operations by reducing hysteresis loss. This property is critical for large scale applications such as tires, heavy duty conveyor belts, and industrial rollers that face continuous high speed use, as reduced heat buildup extends product lifespan and prevents premature degradation The material’s precisely controlled molecular weight distribution plays a vital role in maintaining consistent processing properties, ensuring stable curing performance and reproducible mechanical results across production cycles. Polybutadiene Rubber1220(PBR) integrates seamlessly with natural rubber, SBR, NBR, and various other synthetic polymers to create hybrid formulations that balance strength, elasticity, and chemical resistance. This versatility makes it an adaptable solution for a wide range of uses in the elastomer industry. Furthermore, its low glass transition temperature significantly improves performance in cold environments by enhancing flexibility and reducing brittleness. Products made from this rubber showcase excellent dimensional stability, crack resistance, and prolonged durability under mechanical strain.

Polybutadiene Rubber 1220 (PBR)

Polybutadiene Rubber 1220 (PBR) is a high-quality synthetic rubber designed with a high cis content to ensure outstanding elasticity, durability, and minimal heat buildup during dynamic use. It exhibits excellent resistance to fatigue and cracking under repetitive stress, along with stable processing characteristics and impressive mechanical strength in demanding conditions. This versatile material excels in various challenging applications, such as high-performance tires, industrial rubber parts, conveyor belts, and molded products for high-impact uses, particularly in cold climates and under heavy operational loads.

- الوصف

- Key Benefits

- Technical Specifications

- Quality Contorol

- Application

- Standards and Certifications

Key Benefits

The key advantage of Polybutadiene Rubber1220(PBR) lies in its outstanding dynamic performance and exceptional durability, offering a balance of engineering excellence and operational cost savings.

Low Hysteresis and Energy Efficiency: Polybutadiene Rubber1220(PBR)'s very low hysteresis significantly reduces energy loss during repeated deformation cycles. For tire manufacturers, this means reduced rolling resistance, translating to lower fuel consumption and a longer range for electric vehicles. Its excellent thermal stability minimizes the risk of structural degradation, such as casing fatigue, enhancing both safety and longevity.

Superior Abrasion and Wear Resistance: Products made with Polybutadiene Rubber1220(PBR) maintain their structural integrity even in high-friction conditions. This makes it an ideal material for components subjected to heavy wear, such as tire treads, industrial wheels, mechanical transmission parts, and heavy duty rubber tracks. Its high resilience also provides excellent shock absorption, making it well suited for applications like sporting equipment and vibration damping components where impact resistance is critical.

Cold Climate Flexibility: Featuring a remarkably low glass transition temperature (approximately -106°C), Polybutadiene Rubber1220(PBR) remains flexible in extremely cold conditions. This attribute is especially valuable for winter tires, outdoor mining equipment, and automotive parts exposed to harsh temperature variations, ensuring reliable, crack-resistant performance when other elastomers could become brittle.

Efficient Compounding and Curing: The clean and uniform polymer structure of Polybutadiene Rubber1220(PBR) (characterized by low gel content and minimal impurities) enhances curing efficiency and mechanical strength when combined with fillers. This leads to less material waste, smoother manufacturing processes such as extrusion and molding, and highly uniform finished products.

Enhanced Multi-Polymer Blending: When used in multi-polymer formulations, Polybutadiene Rubber1220(PBR) serves as a reinforcing agent. Blended with natural rubber or SBR, it significantly improves properties like tear resistance, tensile strength, and flex life. This makes it an invaluable ingredient for demanding applications, including heavy-duty conveyor belts, large industrial tires, and engineered rubber components requiring both superior strength and robust dynamic performance.

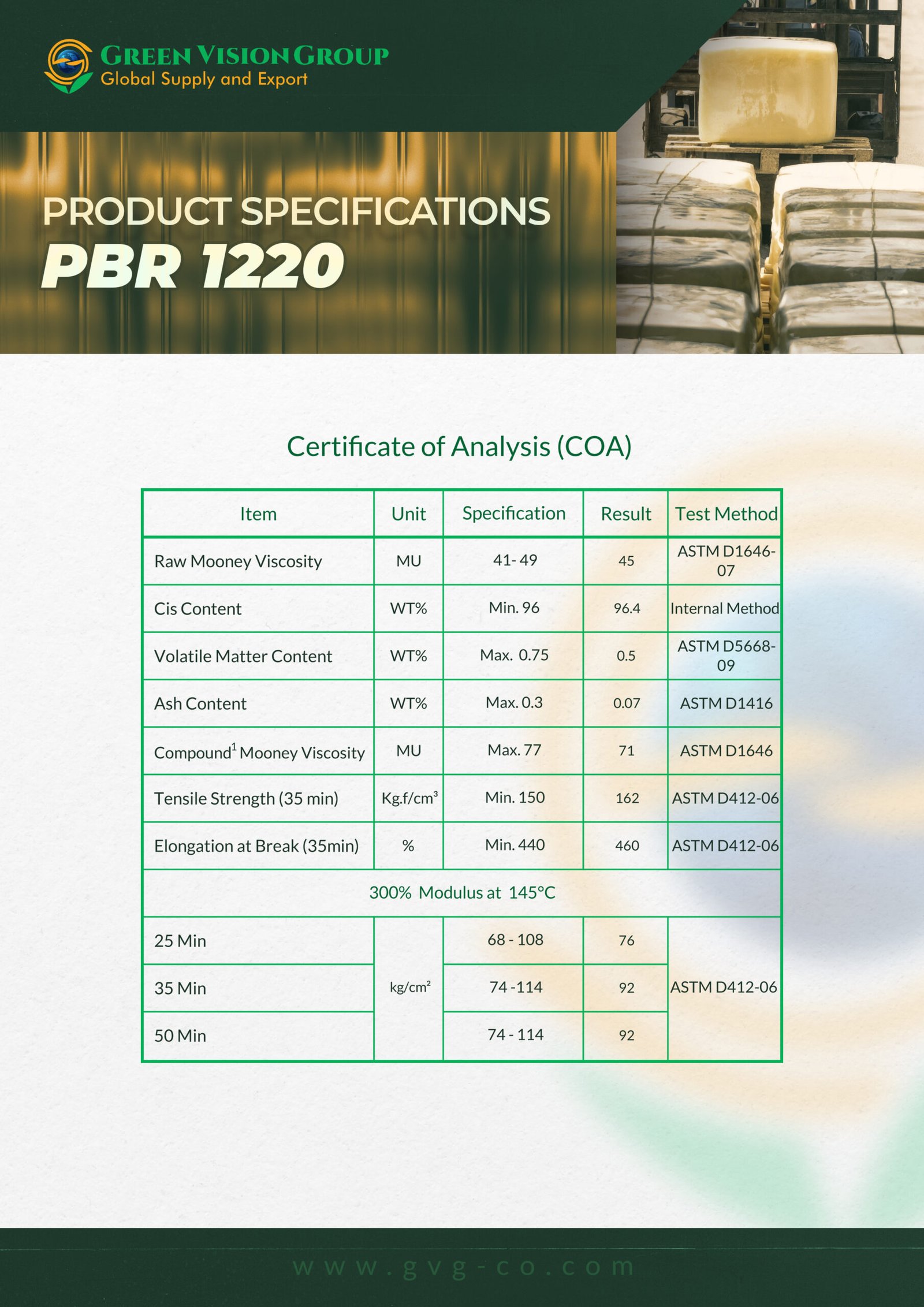

Technical Specifications

| Item | Unit | Specification | Result | Test Method |

|---|---|---|---|---|

| Raw Mooney Viscosity | MU | 41-49 | 45 | ASTM D1646-07 |

| Cis Content | WT% | Min. 96 | 96.4 | Internal Method |

| Volatile Matter Content | WT% | Max. 0.75 | 0.5 | ASTM D5668-09 |

| Ash Content | WT% | Max. 0.3 | 0.07 | ASTM D1416 |

| Compound1 Mooney Viscosity | MU | Max. 77 | 71 | ASTM D1646 |

| Tensile Strength (35 min) | Kg.f/cm³ | Min. 150 | 162 | ASTM D412-06 |

| Elongation at Break (35 min) | % | Min. 440 | 460 | ASTM D412-06 |

| 300% Modulus at 145°C (35 min) | Kg.f/cm² | 74-114 | 92 | ASTM D412-06 |

| 300% Modulus at 145°C (50 min) | Kg.f/cm² | 74-114 | 92 | ASTM D412-06 |

Quality Contorol

Application

Polybutadiene Rubber1220(PBR) is an exceptionally adaptable synthetic rubber, celebrated for its remarkable dynamic performance and vital contributions across various industries where durability, resilience, and energy efficiency are critical.

Dominance in the Tire Industry: Its foremost application is in the tire industry. High cis polybutadiene is a key component in the production of treads, sidewalls, and carcass parts. With low hysteresis and excellent resilience, Polybutadiene Rubber1220(PBR) enables tire manufacturers to achieve reduced rolling resistance, enhanced fuel efficiency, and improved wear resistance. These attributes make it indispensable for passenger car tires as well as high-performance, off-road (OTR), mining, and heavy duty commercial tires. These products face extensive operational challenges, such as high loads and cyclical fatigue. Additionally, blending Polybutadiene Rubber1220(PBR) with SBR and NR has become the industry standard to optimize wet traction without compromising tread life.

Essential in Automotive Components: Polybutadiene Rubber1220(PBR) plays a significant role in automotive engineering, especially in the production of high-stress parts like suspension bushes, engine mounts, vibration dampers, and rubber-metal bonded components. Its capability to absorb high-frequency vibrations and impact shocks while maintaining flexibility ensures longer lifespans for these critical parts, directly enhancing vehicle safety and durability. Furthermore, its reliable molding and vulcanization properties allow manufacturers to create defect-free components that meet strict OEM requirements consistently.

Industrial and Mining Applications: This material is a trusted choice for manufacturing conveyor belts, mechanical rollers, rubber tracks, and industrial vibration isolators. Its superior abrasion resistance and stability under high-frequency stress cycles minimize maintenance needs and mitigate downtime. These advantages make it indispensable for demanding sectors such as mining, construction, and heavy logistics, where equipment operates under extreme conditions. In conveyor belts, for instance, high cis polybutadiene improves both performance and safety with enhanced durability in cover and skim compounds.

Advanced Footwear Solutions: The footwear sector relies on Polybutadiene Rubber1220(PBR) for producing durable athletic and industrial safety soles with enhanced elasticity and grip. Its excellent rebound resilience and resistance to flex cracking make it a prime choice for premium sports shoes and work boots that need sustained performance and comfort. The material’s flexibility at low temperatures ensures that soles remain non slip and functional even in freezing environments.

Versatility in Molded and Extruded Products: Polybutadiene Rubber1220(PBR) reinforces various molded and extruded goods, including rubber hoses, precision gaskets, grommets, and impact resistant components. Its ability to retain flexibility in low temperature conditions is particularly beneficial for applications in cold climates, industrial refrigeration systems, or equipment exposed to freezing temperatures, where conventional elastomers often fail. The material's durability helps maintain the dimensional stability of precision parts over time.

Consumer and Sporting Goods Excellence: Consumer products also benefit from the unique properties of Polybutadiene Rubber1220(PBR). It finds usage in items such as sporting goods like golf ball cores, shock absorbing pads, and durable household components. Its longevity and high resilience ensure superior performance even during sustained use across these applications.

Standards and Certifications

| Standard / Certification | Description |

|---|---|

| ISO 9001 | Quality Management System ensuring controlled production from raw material sourcing to polymerization, packaging, and final inspection. |

| ISO 14001 | Environmental Management System focused on reducing waste, energy efficiency, and responsible chemical handling. |

| ISO 45001 | Occupational Health & Safety Management ensuring safe manufacturing practices during polymerization, handling, and packaging. |