Styrene Butadiene Rubber1712(SBR) is an oil extended Styrene-Butadiene Rubber engineered to deliver a well-balanced combination of mechanical performance, superior processing stability, and cost-effectiveness for large-scale industrial use. Known for its adaptability, this grade finds extensive application in industries such as tires, footwear, conveyor belts, and molded rubber products, establishing itself as one of the most versatile synthetic rubbers on the global market.

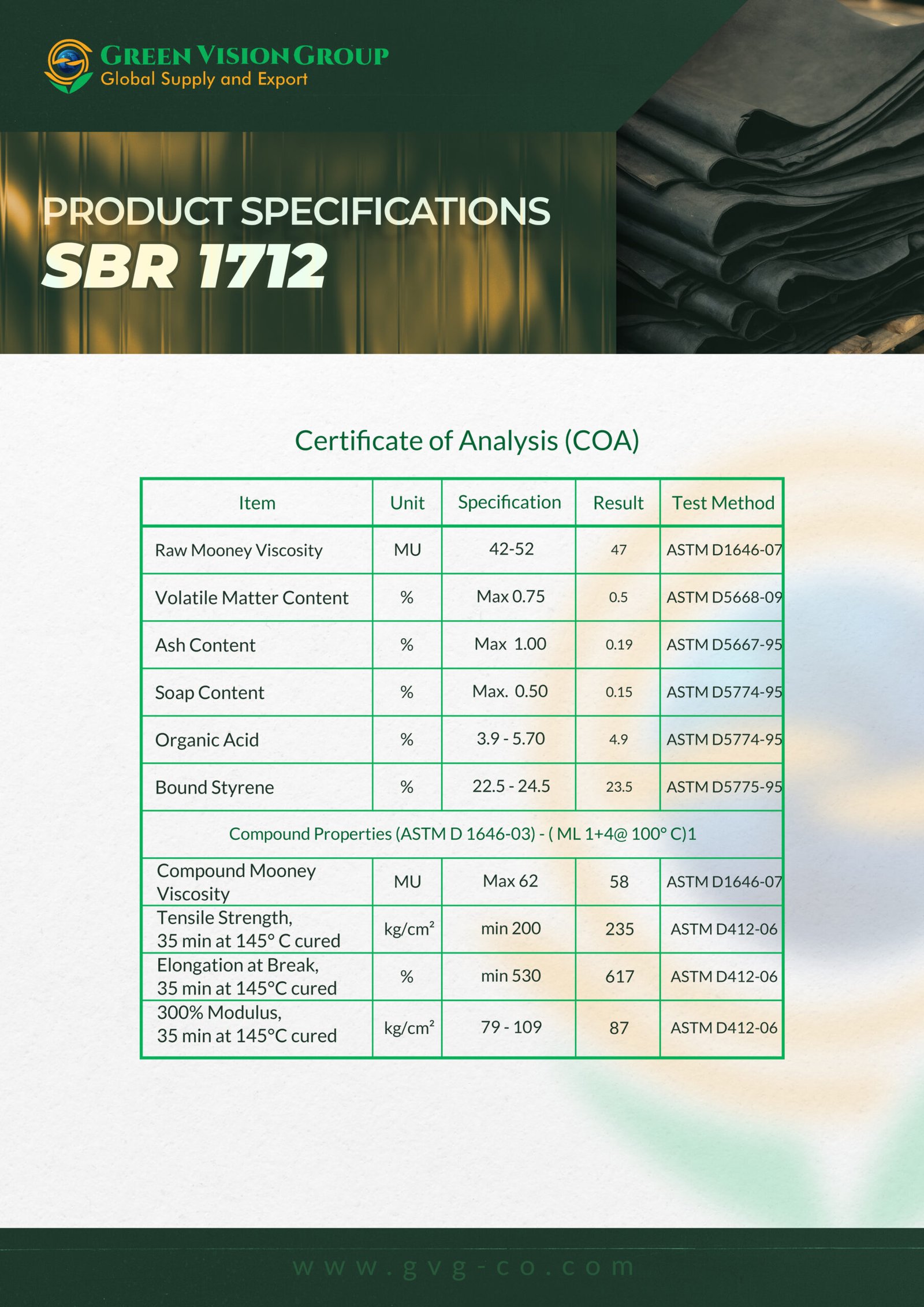

The material contains approximately 23.5% styrene and is extended with 37.5 phr of aromatic or TDAE oil. This specific formulation enhances elasticity, optimizes dynamic performance, and reduces compound viscosity during the mixing process, offering significant processing advantages.

Styrene Butadiene Rubber1712(SBR)’s appeal lies in its ability to combine functional performance with economic practicality. By incorporating oil extension, the overall polymer cost per kilogram decreases while improving filler dispersion, significantly simplifying the compounding process. The resulting rubber exhibits strong abrasion resistance and excellent aging durability when appropriately stabilized, ensuring reliable performance under diverse temperature conditions. These features make it a preferred choice for high demand applications such as tire treads, automotive parts, technical rubber goods, hoses, and vibration isolation components.

Chemically, Styrene Butadiene Rubber1712(SBR)offers consistency in its polymer microstructure, enabling predictable curing and stable mechanical properties. It blends seamlessly with natural rubber, butadiene rubber (BR), and fillers such as carbon blacks from grades N220 to N660. Additionally, its compatibility extends to a wide range of antioxidants, plasticizers, and vulcanizing agents, making it suitable for both high-performance and general purpose formulations.

From a manufacturing standpoint, Styrene Butadiene Rubber1712(SBR)demonstrates exceptional processing efficiency with smooth mastication, low heat generation during mixing, and outstanding extrudability, even under high-shear conditions. These qualities result in uniform surface finishes and precise dimensional accuracy in extruded products such as rubber sheets, tubes, profiles, and gaskets.

In tire production one of its primary applications Styrene Butadiene Rubber1712(SBR)enhances wet traction, improves tread wear resistance, and reduces rolling resistance when optimized with silica or high structure carbon black grades. This aligns with modern energy efficiency requirements, allowing tire manufacturers to produce products that meet various international regulatory standards.

Overall, Styrene Butadiene Rubber1712(SBR)stands out as a reliable and versatile synthetic rubber solution. It enables manufacturers across multiple industries to achieve consistent product quality, increased efficiency, and superior performance throughout their production processes.