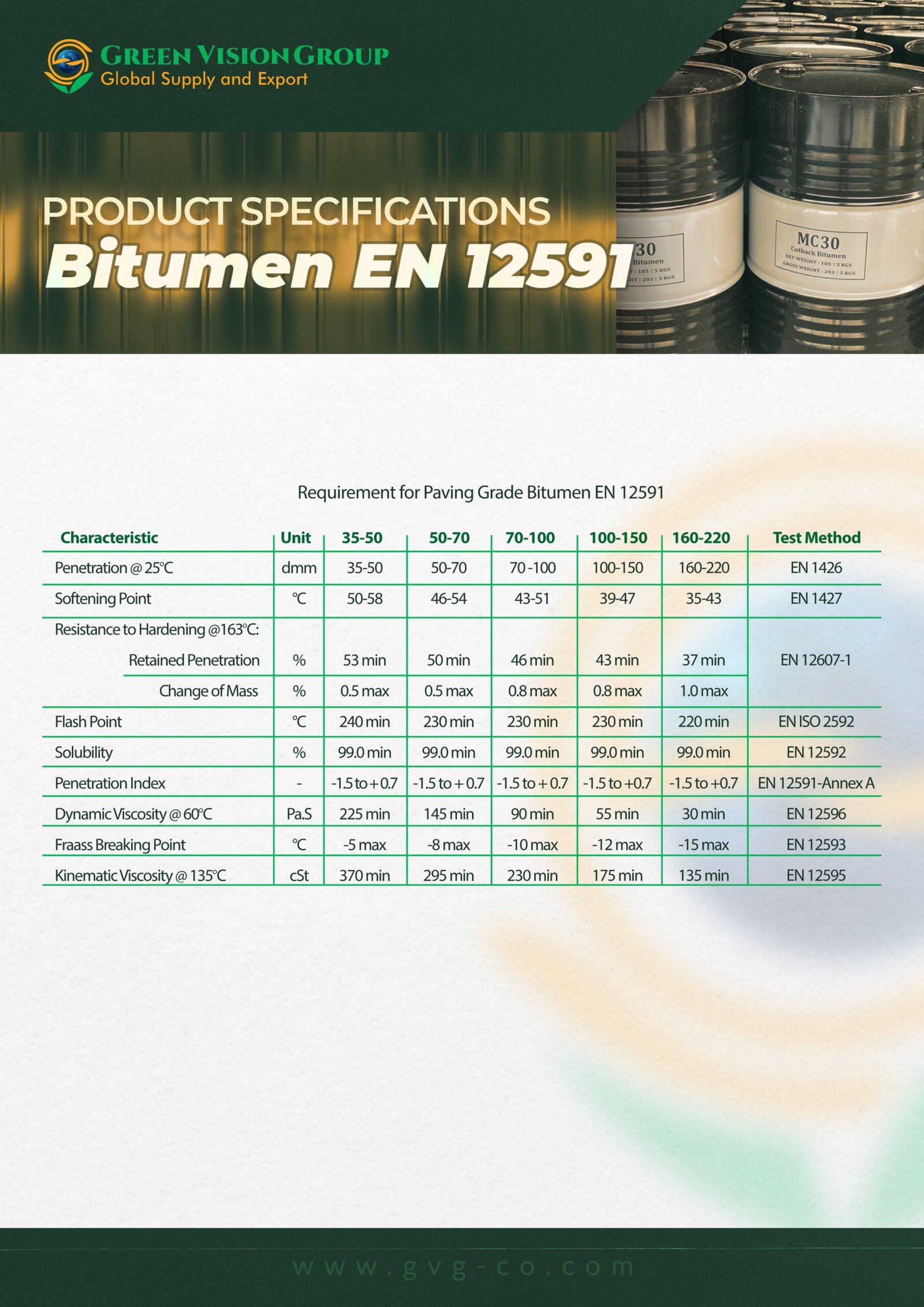

Bitumen EN 12591 is a premium paving-grade bitumen developed to meet the rigorous European Standard EN 12591, which sets strict criteria for the physical, chemical, and rheological properties required in modern road construction and asphalt production. This high-quality binder is produced using a refined process that utilizes carefully selected crude oils and vacuum residue feedstock, ensuring consistent purity, stability, and performance across all batches. This standardized bitumen is available in several penetration grades—35/50, 50/70, 70/100, 100/150, and 160/220 tailored to suit specific climatic conditions, pavement designs, and traffic levels. Penetration values, measured in tenths of a millimeter, indicate the bitumen’s hardness and resistance to deformation. Harder grades like 35/50 are highly resistant to rutting and ideal for hot climates or heavily trafficked highways, while softer grades such as 160/220 offer flexibility in cold environments, reducing the risk of cracking due to freeze–thaw cycles. With its distinctive dark, semi-solid, highly viscous hydrocarbon structure, Bitumen EN 12591 provides exceptional adhesion to mineral aggregates, significantly improving the durability, cohesion, and mechanical stability of asphalt layers. Its well-calibrated softening point, high flash point, and controlled viscosity make it highly compatible with both batch and continuous asphalt mixing plants, facilitating smooth pumping, uniform mixing, and efficient paving processes. Renowned for its physical resilience and chemical stability, this bitumen performs reliably under varying temperatures, oxidation, and intense traffic stresses. Its high solubility (typically exceeding 99%) and low impurity levels contribute to predictable behavior during heating and blending, minimizing residue buildup and operational challenges. EN 12591 bitumen is widely used in various applications within the construction industry, including:

– Highways and expressways

– Urban and rural roads

– Airport runways and taxiways

– Asphalt concrete and hot-mix asphalt production

– Waterproofing of bridge decks

– Surface treatments and sealing applications

Its adaptability also extends to industrial applications such as waterproofing membranes, bituminous emulsions, polymer-modified bitumen, and specialized coatings. The chemically stable profile ensures reliability and compatibility for these uses. Acknowledged globally for its consistent quality and compliance with international standards, Bitumen EN 12591 is manufactured under robust quality assurance programs. It is tested against leading European regulations, such as EN 1426 (Penetration), EN 1427 (Softening Point), EN 12592 (Solubility), and EN 12593 (Fraass Breaking Point), among others. Its demonstrated reliability and adherence to global standards make it a top choice for regulatory bodies, private contractors, and large-scale infrastructure projects across Europe, Asia, Africa, and the Middle East.