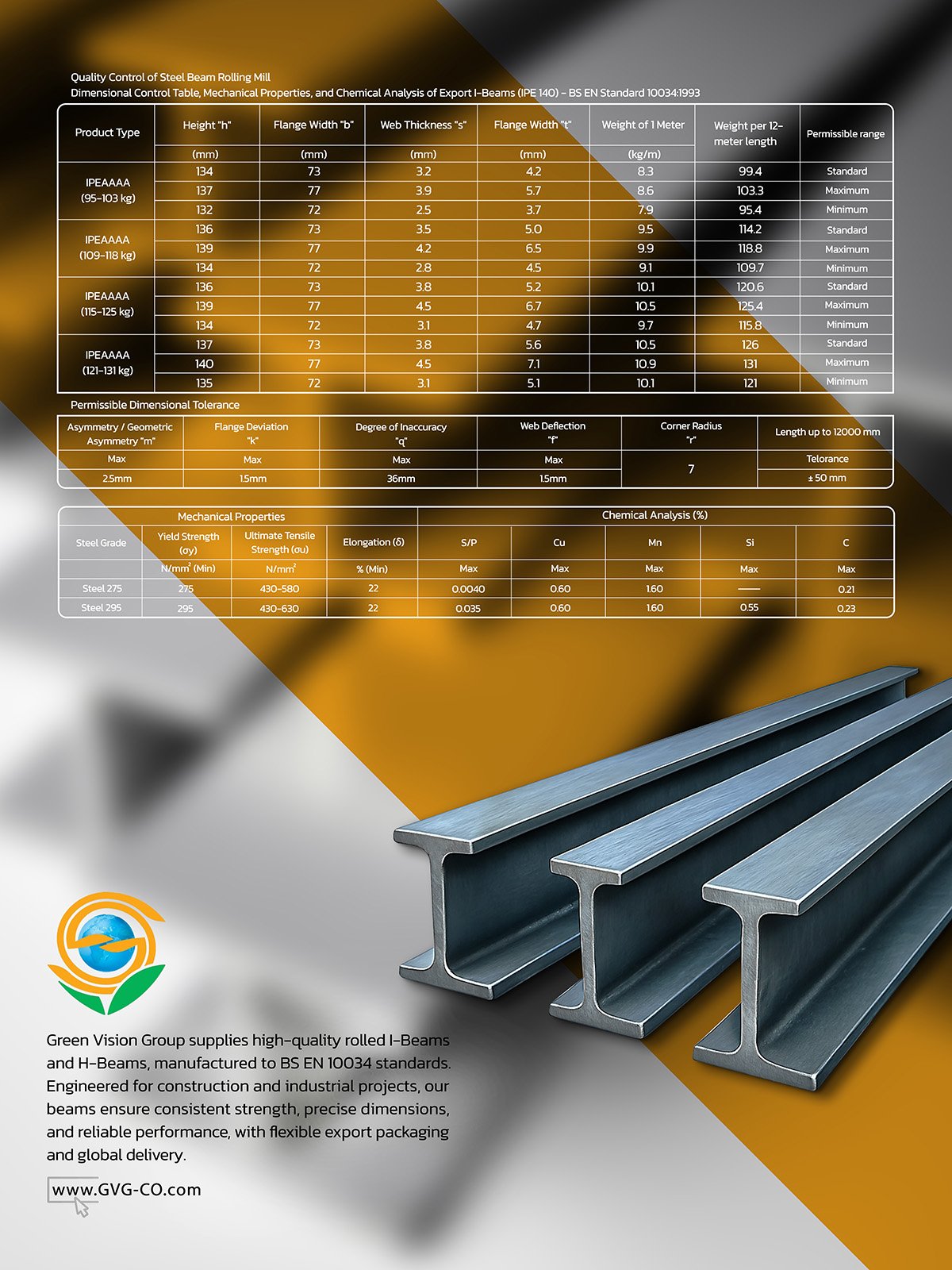

At Green Vision Group, we supply and export rolled steel beams manufactured through a precision-controlled beam rolling process that meets international standards such as BS EN 10034.

Our production facilities use advanced hot rolling mills and automated dimensional control systems to ensure uniform shape, excellent surface finish, and consistent mechanical properties across every beam.

Rolled I-Beams and H-Beams from Green Vision Group are engineered for construction, industrial infrastructure, bridges, and high-rise buildings, offering exceptional load-bearing strength and long-term reliability.

Each beam undergoes strict quality testing for chemical composition, tensile strength, and dimensional accuracy, ensuring optimal performance in demanding environments.

We provide flexible export packaging options and global logistics support, ensuring safe and efficient delivery to clients in the Middle East, Africa, and Europe.

Standards & Certifications

Green Vision Group’s rolled I-Beams and H-Beams are manufactured in accordance with international standards to ensure quality and reliability:

-

BS EN 10034 – European standard for structural steel I and H sections

-

ISO 9001 – Quality management system certification

-

Strict internal testing for chemical composition, tensile strength, and dimensional accuracy

These standards guarantee that every beam meets global quality requirements, providing safety, consistency, and optimal performance in construction and industrial applications

Applications

Green Vision Group’s rolled I-Beams and H-Beams are ideal for a wide range of construction and industrial projects, including:

-

High-rise buildings and commercial complexes

-

Bridges and transportation infrastructure

-

Industrial facilities and warehouses

-

Structural frameworks for civil engineering projects

-

Heavy-duty construction requiring high load-bearing capacity

Each beam is engineered to ensure durability, stability, and compliance with international standards, making them suitable for demanding environments worldwide