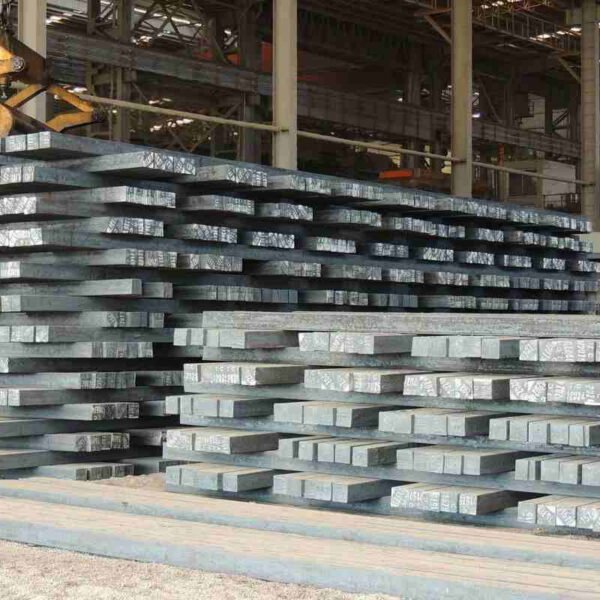

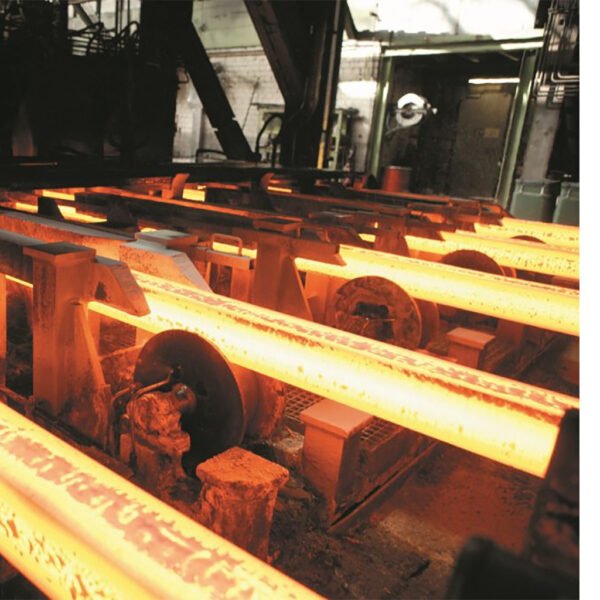

Steel slabs are a crucial intermediary in the steel production process, characterized by their rectangular cross-section and predominantly produced through continuous casting (CCM), with rolled steel ingots occasionally used as an alternative. Serving as the primary raw material for manufacturing a variety of flat steel products, these slabs are valued for their uniform structure and well-regulated chemical composition, which form a reliable base for further processing. Widely utilized in producing hot-rolled coils and plates, steel slabs can be further transformed into cold-rolled sheets, galvanized or aluminized sheets, color-coated coils, welded pipes, structural profiles, and other fabricated steel components. Their consistent thickness and smooth surface quality facilitate highly efficient rolling and forming processes, helping achieve end products with precise dimensions and dependable mechanical properties. Available in various grades, such as carbon steel, low-carbon steel, alloy steel, and stainless steel, steel slabs cater to diverse industrial needs. Each grade is engineered to exhibit specific characteristics be it strength, ductility, corrosion resistance, or heat resistance making them suitable for critical applications across industries like automotive manufacturing, construction, home appliances, shipbuilding, pressure vessels, energy projects, and heavy industrial machinery. To uphold quality standards and ensure optimal performance, steel slabs undergo rigorous inspection and testing procedures. These include chemical composition analysis, ultrasonic testing, surface examination, and dimensional checks. Produced in a range of thicknesses, widths, and lengths, they are tailored to meet individual customer specifications and manufacturing requirements. Thanks to their structural robustness, adaptability in processing, and versatile applications, steel slabs remain an indispensable part of global steel supply chains and are integral to large-scale industrial advancements.

Steel Slab – High-Quality Raw Materials for Industrial Applications

Steel slabs are semi-finished products made of steel, featuring a rectangular cross-section. These are primarily produced through continuous casting and serve as the key raw material for manufacturing flat steel products such as hot-rolled coils, plates, cold-rolled sheets, and coated steels. With a uniform structure, precise chemical composition, and consistent surface quality, they facilitate efficient downstream processing and ensure dependable mechanical performance. Available in various grades including carbon, alloy, and stainless steel, steel slabs cater to diverse applications across industries like construction, automotive, energy, shipbuilding, and heavy machinery.

- الوصف

- Technical Specifications

- Standards & Certifications

- Application & Industries

- Packaging & Export Details

Technical Specifications

| Attribute | Details |

|---|---|

| Dimensions | Width: 900–2000 mm | Thickness: 150–300 mm | Length: 4–12 meters |

| Approximate Weight | 10–30 tons per piece |

| Production Method | Continuous Casting (CCM) or Rolling of Large Ingots |

| Available Grades | ST37, ST52, SAE1006, SAE1008, API 5L, ASTM A36, Q235B, S235JR, and more |

| Main Applications | Hot/cold rolled coils, galvanized sheets, pipes, profiles, automotive parts |

| Quality Levels | Commercial, Industrial, Precision Rolling, Export Grade |

Standards & Certifications

Steel slabs are available in compliance with internationally recognized standards depending on grade and application:

- ASTM A36 / A283 / A572 (USA) – Structural and industrial applications

- EN 10025 / EN 10130 / EN 10204 (Europe) – Construction and flat product applications

- JIS G3101 / JIS G3131 (Japan) – Automotive and appliance industry

- API 5L – Oil and gas pipe manufacturing

- GOST 14637 / GOST 5520 (Russia) – Heavy-duty and industrial applications

- ISIRI 2833 (Iran) – National standard for hot-rolled flat steel products

All steel slabs come with Mill Test Certificates (MTCs) including full chemical and mechanical analysis.

Application & Industries

Steel slabs are utilized in multiple downstream industries and manufacturing processes, including:

- Flat steel product manufacturing (HR/CR/GI/PPGI)

- Pipe and profile production

- Automotive body parts and structural components

- Construction and infrastructure projects

- Pressure vessels and boilers

- Marine and shipbuilding industries

- Energy and heavy industrial equipment manufacturing

Packaging & Export Details

- Packaging: Bulk shipment or steel-strapped bundles

- Minimum Order Quantity: As per agreement

- Shipping Destinations: Gulf Region, Africa, Southeast Asia, and worldwide

- Delivery Terms: FOB, CIF, CFR available upon request