Iron billets are semi-finished steel products that serve as a fundamental material in producing various steel goods. These billets are created by melting iron ore or steel scrap in specialized furnaces and then casting the molten metal into standardized molds. The production process begins with heating raw materials in a furnace until they melt completely. Once the desired temperature is achieved, the molten metal is poured into molds where it cools and solidifies into the intended shape.

These molds may have circular, square, rectangular, or irregular cross sections. The iron billet’s chemical composition and quality can vary depending on the type of furnace employed, which could be an electric arc furnace, induction furnace, or blast furnace. Acting as a critical intermediary between raw materials and finished steel products, iron billets are processed further in rolling mills to create rebar, I-beams, steel sheets, and other profiles. Without iron billets, the rolling and shaping of steel materials would become significantly more challenging and cost prohibitive. Click to view billet ingots

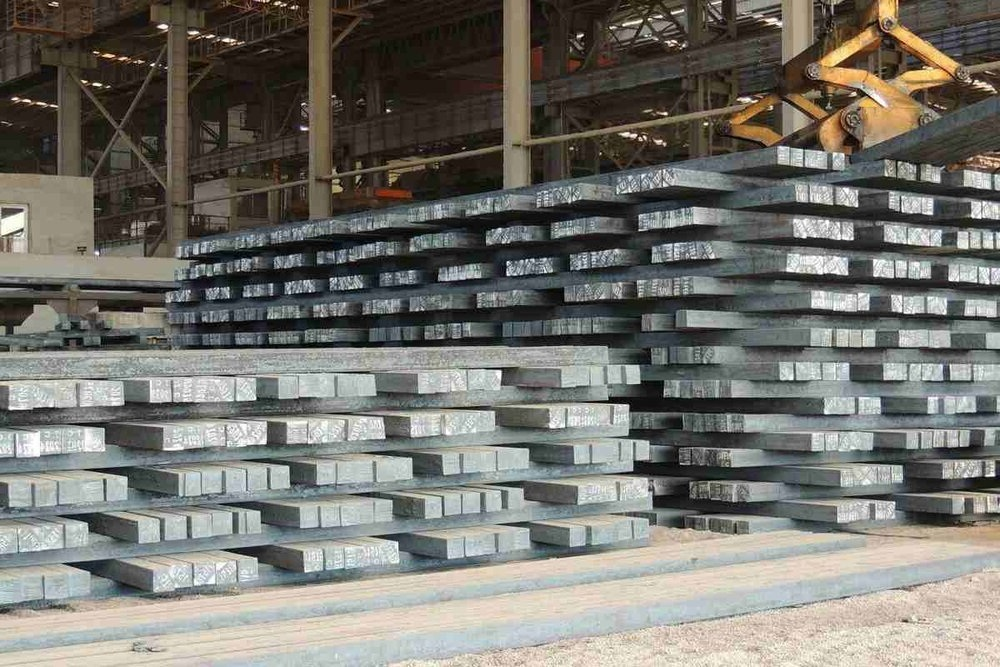

In appearance, iron billets typically have a rough surface that may be coated with oxide layers, which are removed during later processing stages. Their weight varies widely according to their dimensions, ranging from several dozen kilograms to multiple tons. One of the key benefits of iron billets is their ease of storage and transportation. Manufacturers often produce them in large quantities and store them until required for production, aiding in operational efficiency and cost management.

The quality of the billet directly influences the quality of the final steel products. As such, billets commonly undergo chemical analyses and mechanical testing to meet industry standards. Impurities or unwanted elements in the billet can lead to significant issues in subsequent manufacturing processes. Iron billets form the backbone of modern steelmaking.

Classification by Shape and Application

Iron billets come in three primary categories: billet, bloom, and slab. Each serves distinct applications and usage, billets are typically used for producing rebar and wire rods, blooms for heavy items like I-beams and channels, and slabs for sheet production. Globally, the steel industry generates millions of tons of iron billets annually, a substantial portion of which is consumed domestically or exported. Click to view bloom ingots

Prices within the billet market significantly affect overall steel costs, as changes in billet pricing directly impact the cost of finished products. In conclusion, iron billets form the backbone of the steel industry. They play an indispensable role in sectors such as construction, machinery production, energy infrastructure, and transportation. Without them, these industries would face considerable setbacks, underscoring their critical importance in the steel production chain. Iron billet standardization enables global interoperability. Shape selection determines downstream efficiency. Market dynamics hinge on billet availability and quality. These factors collectively define industrial readiness.

Shape-Based Types and Their Uses

Iron billets are divided into different categories based on their shape and production process, each with distinct features and applications. These classifications are essential for selecting the right billet type for manufacturing various steel products, as each type is tailored for specific purposes. One prevalent type is the billet, sometimes referred to as “shamshal” in certain regions.

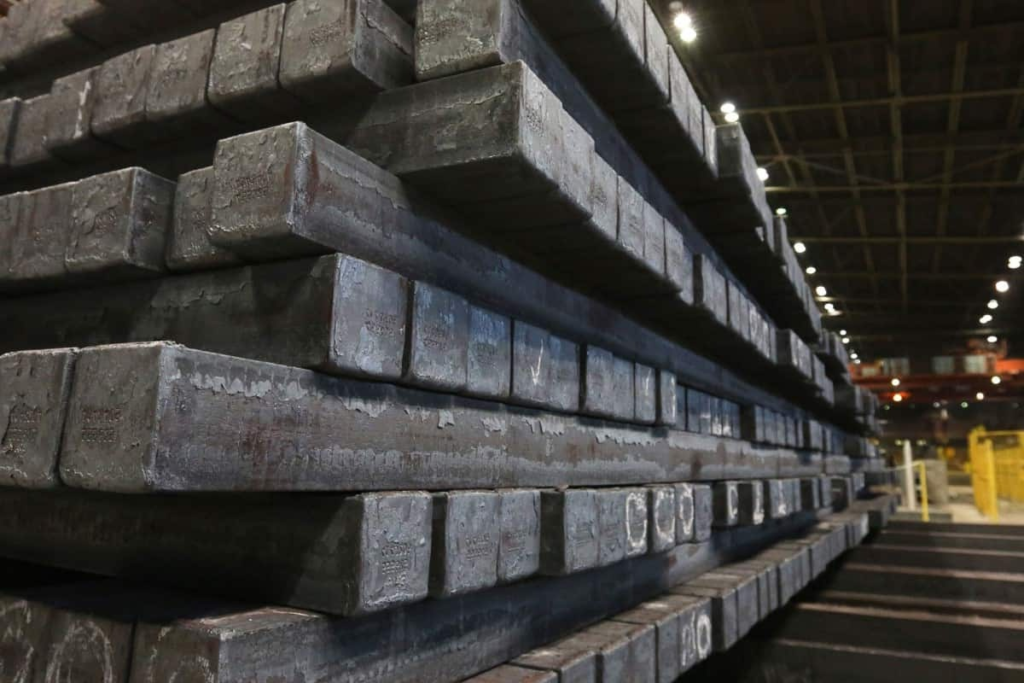

Typically featuring a square cross section with sides measuring less than 15 centimeters, this billet is extensively used for producing rebar, wire rods, and light structural profiles. Its high ductility and ease of rolling make it suitable for construction and light industrial applications. Blooms represent another category, characterized by a larger square or rectangular cross section, generally exceeding 15 centimeters. Click to view billet ingots

These are mainly utilized in the manufacture of heavy structural steel products like I-beams, channels, and railway rails. With their larger size, blooms offer greater strength and load-bearing capacity, making them ideal for large-scale industrial and infrastructure projects. Slabs, the third type, have a wide, flat rectangular cross-section and are mainly used for flat steel products such as hot-rolled and cold rolled sheets, plates, and patterned steel. Their shape is particularly well suited for flat rolling mills and finds applications in automotive manufacturing, shipbuilding, and household appliances. Iron billet shape dictates processing route. Bloom size enables heavy fabrication. Slab geometry supports sheet continuity.

Production Methods and Material Quality

Regarding production methods, the blast furnace process is a common technique. In this approach, iron ore, coke, and flux are melted at high temperatures to produce molten iron, which is then cast into billets. This method is typically employed in large integrated steel plants, resulting in billets with high quality and consistent chemical composition.

Alternatively, electric arc furnaces (EAF) or induction furnaces are used. These methods primarily utilize scrap steel or recycled metal, melted with electric current. This option is more cost-effective and environmentally friendly, popular in smaller or medium sized plants. While the chemical consistency may slightly differ from that of blast furnace billets, these methods allow for faster production and flexible alloy adjustments.

Billets made through continuous casting generally exhibit better quality due to faster and more controlled cooling processes. In contrast, iron billets produced by traditional ingot casting might need additional surface conditioning before rolling. The choice of billet type based on shape and production method directly affects production costs, efficiency, and the quality of the final product. For instance, utilizing a slab for rebar production is not cost effective or energy-efficient due to unnecessary material waste and processing time. Therefore, precise knowledge of iron billet types is crucial for production managers and industrial designers.

Furnace Technologies and Process Selection

Beyond technical aspects, economic factors like raw material prices, furnace availability, and environmental regulations influence the choice of production methods. For example, countries rich in iron ore resources often prefer blast furnace methods, while those lacking such resources may opt for electric arc furnace processes to recycle scrap. Click to view slab ingots.

In conclusion, classifying iron billets by shape into billets, blooms, and slabs and by production methods such as blast furnace, electric arc furnace, and induction furnace processes provides the flexibility needed to meet diverse industrial demands. This diversity is fundamental to the steel industry, streamlining the journey from raw materials to finished steel products. Iron billet furnace choice affects carbon footprint. Blast furnaces offer purity at scale. EAF enables circular economy models. Process alignment ensures cost and quality balance.

Comparative Analysis of Billet Manufacturing

Iron billets are grouped into distinct categories based on their production processes, each offering specific characteristics and applications. This classification allows manufacturers to choose the most suitable production method aligned with market demands and factory capabilities, ensuring the production of high-quality products. One widely used method is the blast furnace process. It involves melting iron ore, coke, and fluxes at extremely high temperatures to produce molten iron. The molten iron is then cast into molds and cooled to form billets. Billets produced this way are of superior quality and are commonly utilized for heavy steel applications. Another popular method is the electric arc furnace (EAF) process, which melts scrap iron and steel using an electric arc.

This approach is typically less expensive than the blast furnace technique and allows greater flexibility in adjusting raw material composition. As a result, it is frequently adopted by small to medium-sized steel plants. The induction furnace process represents a third method, operating similarly to EAF but relying on magnetic induction to melt materials. This method is mainly used for producing specialized alloy billets or for small-scale operations. It offers advantages such as reduced energy consumption and more accurate temperature control. Billets manufactured via continuous casting are typically of higher quality due to the uniform and controlled cooling process, leading to a more refined internal structure. This technique is commonly implemented in larger steel facilities.

Quality Control and Environmental Impact

Conversely, the traditional ingot casting method involves pouring molten metal into individual molds for cooling. Billets made this way often require additional surface treatment and conditioning before further processing. Beyond the production method, billet quality is heavily influenced by the grade of raw materials used. Higher-grade raw materials with carefully managed chemical compositions yield billets with excellent mechanical and chemical properties, making them suitable for demanding applications. Cost considerations also vary significantly across production methods. Blast furnaces, while requiring substantial capital investment and upkeep, are ideal for large-scale, high-quality production. Click to view bloom ingots

In contrast, electric arc and induction furnaces have lower initial costs and are more adaptable for smaller-scale or flexible production needs. Environmental factors are increasingly critical when selecting production methods. Electric arc and induction furnaces consume less energy and facilitate greater recycling of scrap materials, resulting in a lower environmental footprint. These considerations have gained prominence in advanced countries striving for greener industrial practices. Ultimately, selecting a billet production method involves balancing technical capabilities, economic feasibility, and environmental impact. The primary objective remains producing billets of the desired quality at competitive costs while minimizing ecological effects.

Operational and Economic Advantages

The utilization of billets in steel and metal product manufacturing brings numerous benefits that significantly enhance product quality while improving production efficiency. These advantages, both technical and economic, are key to the widespread adoption of billets across various steel industry sectors. One of the primary benefits of using iron billets lies in their uniformity and high quality. Crafted from carefully selected and controlled raw materials, billets provide consistent and predictable mechanical and chemical properties for the resulting products. Billets also play a vital role in reducing material waste during production. Their standardized size and shape allow rolling and forming processes to be carried out more efficiently, minimizing scrap generation and cutting related costs.

Additionally, billets support the integration of advanced equipment and technologies. Their regular form ensures smooth passage through rolling mills, presses, and forming machines, resulting in higher production speed and improved precision. Another benefit is the superior internal structure of billets, which enhances the fatigue and impact resistance of final products. This feature is especially critical for industries such as automotive manufacturing and industrial equipment production. Energy conservation is another significant advantage of billets. As semi finished products that have already undergone melting and initial shaping, billets require less energy for subsequent rolling and processing, making operations more energy efficient.

Design Flexibility and Logistics Efficiency

Billet production also allows for precise control over chemical composition. Alloying elements and additives can be meticulously adjusted during this stage to ensure the performance and quality of the end product meet specified requirements. Moreover, billets offer greater flexibility for product design. Manufacturers can tailor iron billets types and specifications to align with market demands and desired product characteristics, enabling a more customized production approach. The use of billets results in shorter production times as well. Since they arrive as semi finished materials ready for forming or rolling, the initial, labor-intensive stages of production are bypassed, accelerating the overall manufacturing process.

Handling, transportation, and storage also benefit from the use of billets. Their standardized dimensions make them easier, safer, and more cost effective to manage across these logistical aspects. Lastly, the economic advantages of billets cannot be overstated. Reduced production costs, enhanced product quality, and improved process efficiency collectively strengthen a manufacturer’s competitiveness in the global steel market. Click to view billet ingots

Altogether, these factors not only optimize production but also enable companies to secure a leading edge in the highly competitive steel industry landscape. Iron billet standardization drives supply chain reliability.

Global Applications Across Key Industries

Iron billets are among the most vital raw materials utilized across various metal and construction industries. Their controllable physical and chemical properties enable a wide array of industrial applications. As a semi-finished product, billets form the foundation for numerous metal manufacturing processes, later shaped into diverse products on production lines. In the construction sector, iron billets play a key role. They are processed into rebar, I beams, angles, channels, and other essential steel profiles. These components serve as the backbone of reinforced concrete and steel structures, making them indispensable for constructing buildings, bridges, and other civil engineering projects. The automotive industry is another major user of iron billets.

Steel derived from these billets is employed in manufacturing car bodies, chassis, engine parts, and suspension systems. Precise control over billet properties is critical in this field, as vehicle safety and performance heavily rely on the quality of metal components. Iron billets also find extensive application in oil, gas, and petrochemical industries. High-grade steel derived from specifically alloyed billets is required for producing pipes, pressure vessels, offshore platforms, and transmission lines. These parts must endure high pressure, extreme temperatures, and corrosion, necessitating exceptional billet quality. In machinery and industrial equipment production, billets are indispensable for manufacturing heavy mechanical components such as gears, crankshafts, shafts, and pumps. Click to view bloom ingots

Specialized Sectors and Strategic Importance

In this domain, the accuracy of a billet’s chemical composition and internal structure is crucial to ensure the machinery’s durability and reliability. The railway sector similarly depends on iron billets for creating rails, wheels, and various train components. These parts demand high resistance to pressure and wear, which is achievable only with billets of superior quality and precise mechanical properties. Military industries also utilize iron billets extensively. They are used in producing armored vehicles, military equipment components, weaponry parts, and defense machinery. These applications require specialized alloy billets to meet stringent standards for safety and performance. The shipbuilding industry represents another significant consumer of billets.

Steel from billets is used for constructing ship hulls, underwater sections, support structures, engine components, and propellers. Due to harsh marine conditions and exposure to saltwater, billets in this field must offer excellent corrosion resistance. In household appliance manufacturing, billets contribute indirectly to the production of components for refrigerators, washing machines, ovens, air conditioners, and more. The visual appeal, mechanical strength, and longevity of these appliances are closely tied to the quality of the steel originating from billets. Iron billets have become a cornerstone material in modern industries. Without them, advancements in infrastructure, transportation, machinery, and technology would face serious obstacles.

Conclusion

Iron billets are a critical component in the production chain of the metal and steel industries, serving as a cornerstone in converting raw materials into finished goods. Their significance is such that without them, many industrial operations would face notable disruptions. Billets come in various shapes, sizes, and are manufactured using different production techniques.

The choice of billet type whether bloom, billet, or slab depends on the industrial requirements and the intended application. Furthermore, production approaches like blast furnaces, electric arc furnaces, and continuous casting play a major role in determining billet quality. Key properties such as structural uniformity, controlled chemical composition, adequate strength, and high formability have established billets as an essential material across sectors like construction, automotive, machinery manufacturing, defense, and shipbuilding. Click to view bloom ingots

The use of billets offers several advantages, including reduced waste, energy efficiency, enhanced precision and faster production processes. These advantages not only elevate the quality of end products but also help reduce overall manufacturing costs. Advances in technology have paved the way for producing billets with tailored properties designed for specific applications.

Modern industries now demand billets with precise alloy compositions, high corrosion resistance, superior hardness, and excellent weldability. This has driven billet manufacturing toward greater precision and efficiency. Large-scale billet production necessitates sophisticated infrastructure, heavy machinery, and skilled labor. Simultaneously, the growing global demand for steel products has elevated iron billets to the status of a strategic commodity. In international trade, iron billets hold an important position. Nations capable of producing high quality billets gain access to lucrative global markets, while those lacking production capabilities often rely on imports to meet their needs for this critical material. Sustainability and environmental considerations are increasingly shaping billet production processes.

The adoption of methods such as electric arc furnaces and the recycling of scrap iron reduces resource consumption and minimizes emissions, making these approaches more eco friendly. In essence, iron billets are much more than raw materials; they represent the foundation of a complex production system that culminates in the creation of consumer and industrial products. Their influence on industrial economics and national development is profound. Thus, it is crucial for industry professionals, investors, policymakers, and technical students to have a comprehensive understanding of billet types, production processes, benefits, and applications. Such knowledge enables more strategic and innovative decision making within this domain.

No Comment